Overview

CMC in pharma stands for Chemistry, Manufacturing, and Controls, which are essential processes and documentation necessary for the development of pharmaceutical products. These practices ensure the safety, efficacy, and regulatory compliance of drugs. Rigorous CMC practices are critical throughout the drug development lifecycle; they facilitate consistent production and adherence to quality standards. Consequently, these measures play a vital role in safeguarding public health and expediting access to innovative therapies.

Introduction

Understanding the intricacies of Chemistry, Manufacturing, and Controls (CMC) is essential for anyone involved in the pharmaceutical industry. This framework dictates not only the safety and efficacy of medications but also ensures compliance with stringent regulatory standards. As the landscape of drug development evolves, the role of CMC becomes increasingly critical, particularly with the FDA's initiatives aimed at accelerating the approval process for new therapies.

However, approximately 40% of Investigational New Drug submissions face delays due to CMC-related issues. Consequently, how can pharmaceutical companies effectively navigate this complex terrain to ensure timely market access while maintaining high-quality standards?

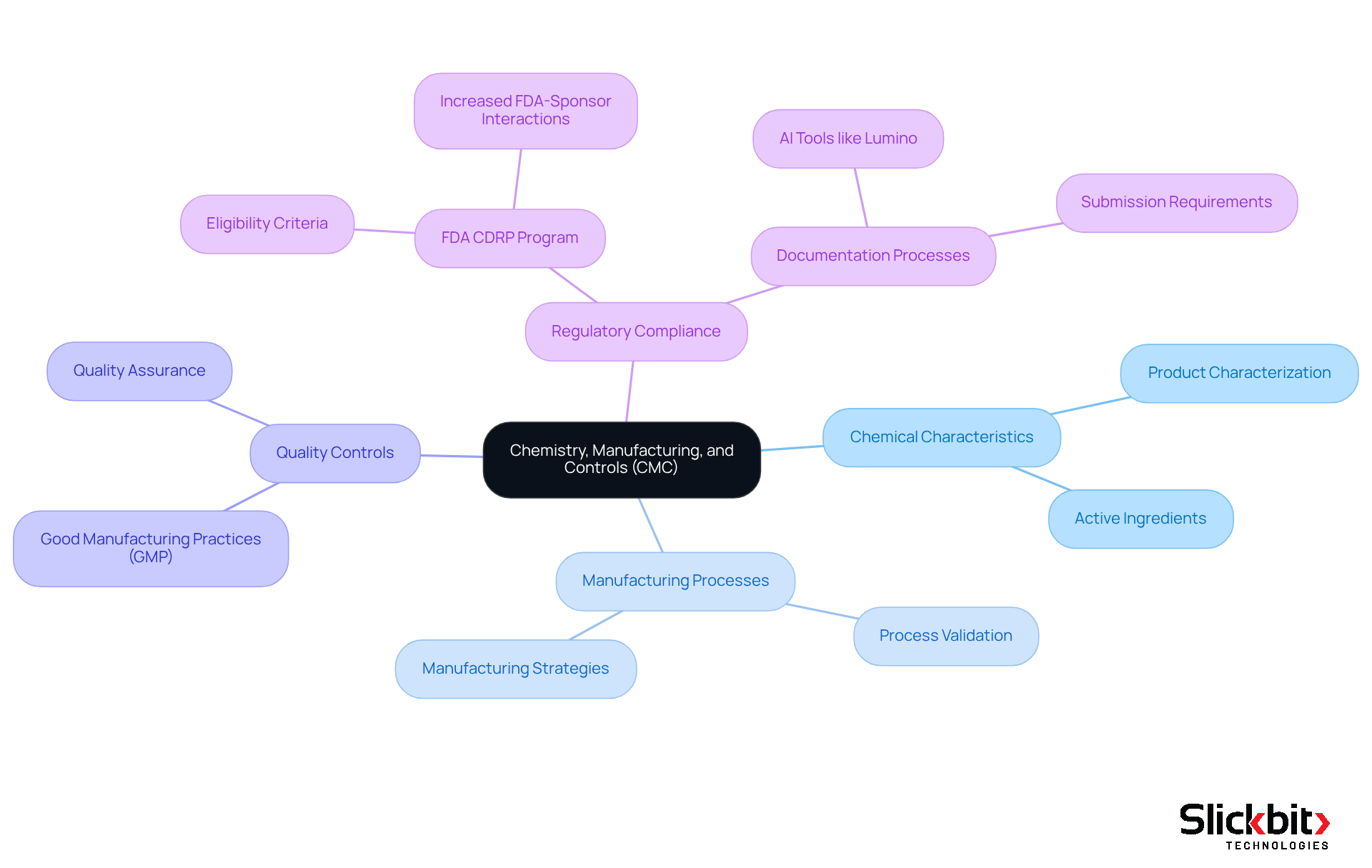

Define CMC: Understanding Chemistry, Manufacturing, and Controls

CMC in pharma means the essential procedures and documentation required for the development of pharmaceutical products. This framework details the chemical characteristics of the medication, the manufacturing processes utilized, and the controls established to ensure quality and regulatory compliance. The significance of CMC in pharma means it is paramount for guaranteeing that medications are safe, effective, and consistently produced to meet rigorous specifications. CMC in pharma means that these activities are integral throughout the medicine development lifecycle, from initial research and development to final product release, ensuring that each phase adheres to necessary regulatory standards.

In 2025, the importance of CMC is underscored by the FDA's Chemistry, Manufacturing, and Controls Development and Readiness Pilot (CDRP), which aims to expedite CMC development for investigational new drug applications (INDs) with accelerated clinical timelines. This initiative underscores the FDA's commitment to enhancing communication with sponsors and facilitating what CMC in pharma means for readiness, ultimately improving patient access to innovative therapies. The CDRP program encourages sponsors to submit comprehensive CMC development plans that outline their timelines and remaining tasks necessary for CMC readiness, fostering collaboration with the FDA for product-specific advice.

In this context, leveraging Slickbit's AI-driven Regulatory Intelligence, including Lumino, can substantially enhance the CMC workflow. Lumino aids pharma teams in accessing accurate, traceable answers from FDA and global guidance documents, while tools like Vault Redact automate the identification and removal of personally identifiable information (PII) and protected health information (PHI) from documents. This approach ensures compliance with regulatory standards while streamlining documentation processes. Consequently, the CDRP program not only promotes innovation but also guarantees that CMC activities align with accelerated clinical development, highlighting what CMC in pharma means for ensuring safety and efficacy. Grace R. Graham, Deputy Commissioner for Policy, Legislation, and International Affairs, emphasizes that successfully expediting CMC readiness may necessitate additional interactions with the FDA during product development.

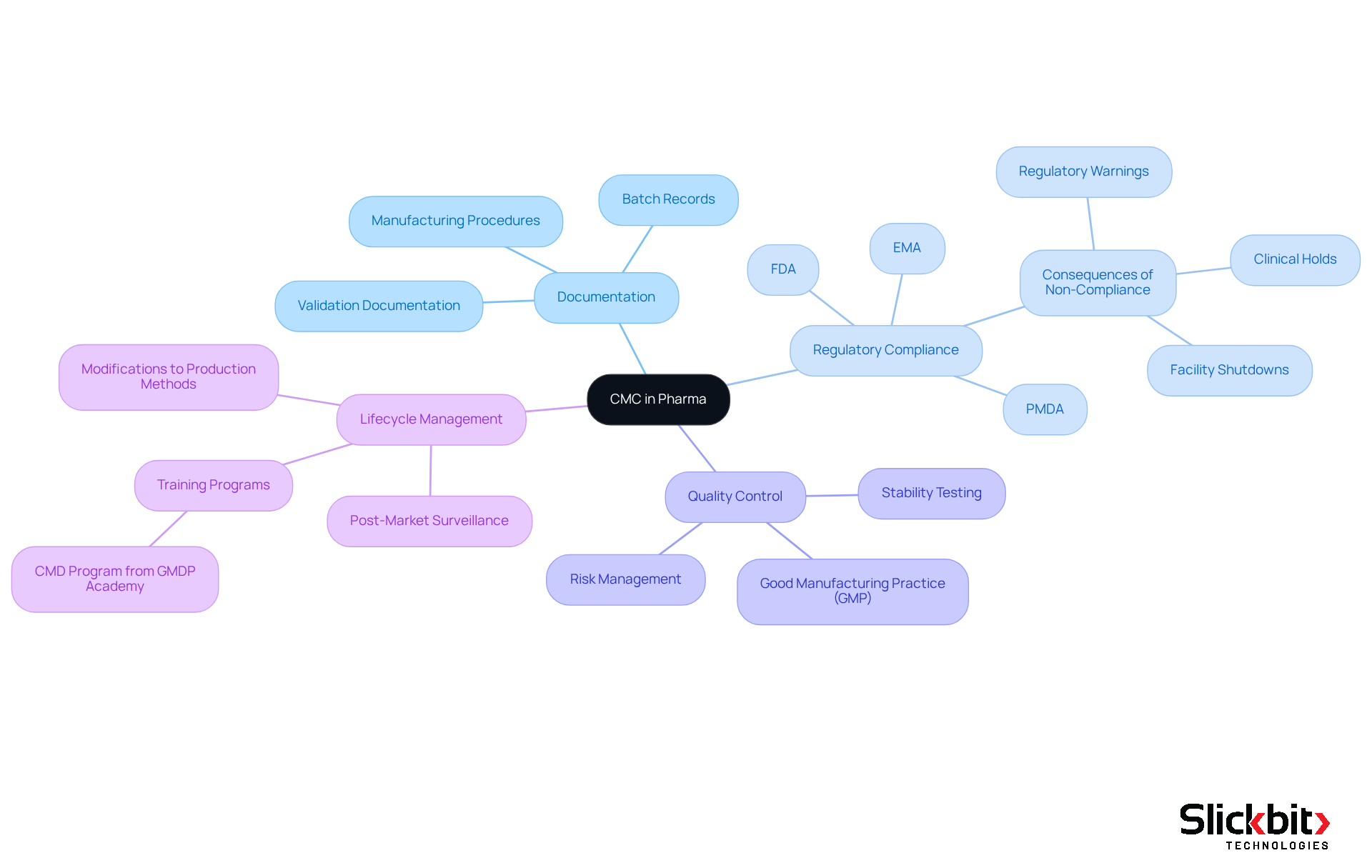

Contextualize CMC: Its Role in Drug Development and Regulatory Compliance

CMC in pharma means playing a pivotal role in medication development, ensuring that every aspect of a medication's chemistry, manufacturing, and quality control is meticulously documented and adheres to regulatory standards. Regulatory bodies worldwide, including the FDA, EMA, and PMDA, mandate comprehensive documentation because CMC in pharma means critical information required for medication approval. This documentation is crucial in demonstrating that a medication can be consistently produced to meet stringent quality standards, thereby safeguarding public health. Notably, around 40% of Investigational New Drug (IND) submissions encounter delays due to issues related to what CMC in pharma means, underscoring the necessity of rigorous CMC practices.

CMC in pharma means that activities extend beyond initial product approval and are vital for ensuring compliance throughout the product's lifecycle. This includes continuous oversight during post-market surveillance and any necessary modifications to production methods. The FDA's heightened scrutiny, evidenced by over 200 Complete Response Letters issued in 2025, highlights that CMC in pharma means the need for robust documentation to avert costly setbacks. CMC in pharma means that key components of CMC documentation comprise batch records, validation documentation, and comprehensive descriptions of manufacturing procedures, all of which are essential for ensuring that investigational drugs are safe for human use and produced in accordance with Good Manufacturing Practice (GMP) standards. Non-compliance with GMP can result in regulatory warnings, clinical holds, and facility shutdowns, highlighting the repercussions of insufficient CMC practices.

Integrating CMC in pharma means considering these elements from the earliest stages of development, allowing pharmaceutical companies to enhance their regulatory submissions and expedite their path to market. The principle 'The method is the result' underscores that initial technical choices significantly influence regulatory approval outcomes. Furthermore, investing in training programs, such as the CMD Program from GMDP Academy, equips professionals with the core competencies needed to navigate regulatory expectations effectively. As Frederik Deroose observes, 'GMP compliance within CMC is crucial for maintaining product consistency across manufacturing batches via validated methods.

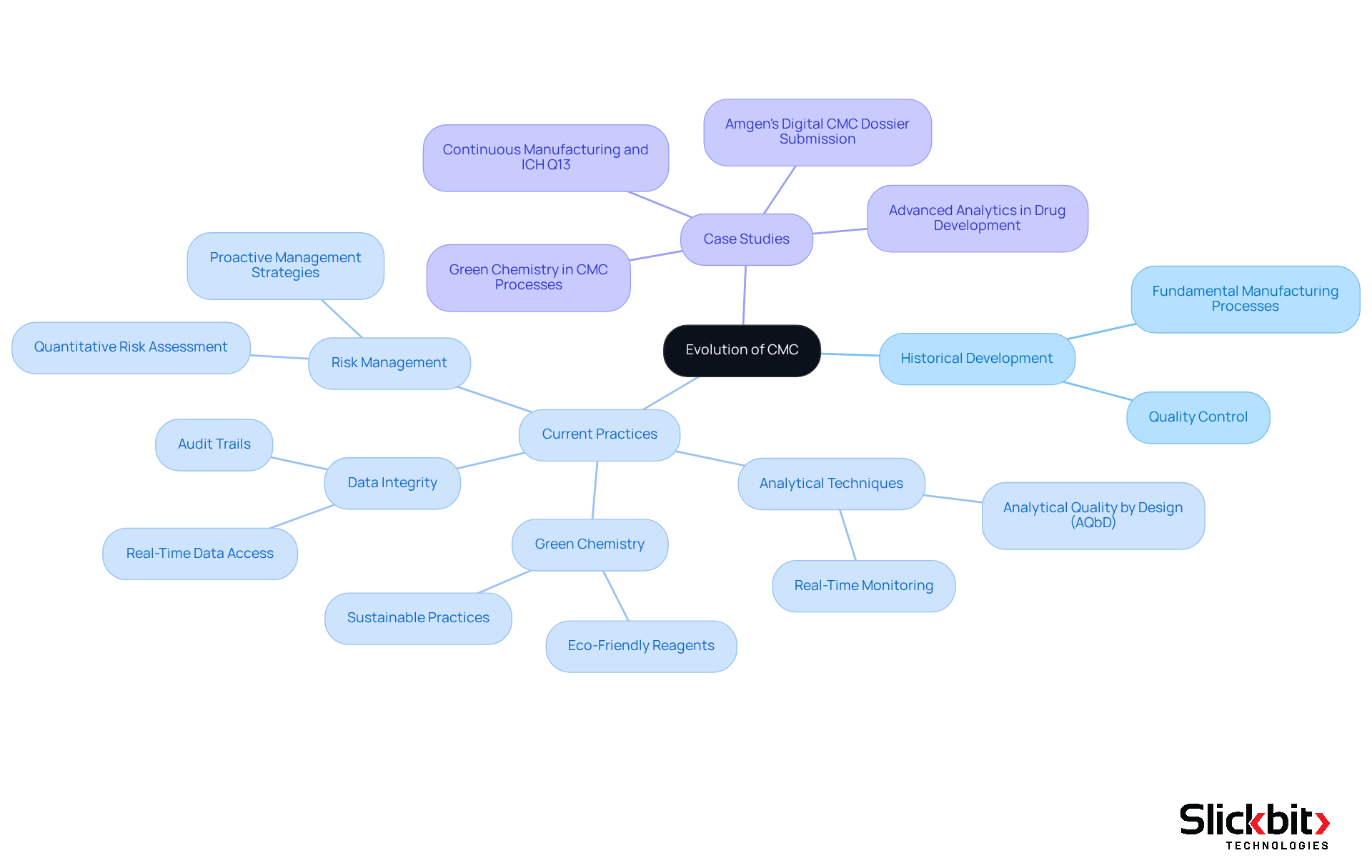

Trace the Evolution of CMC: Historical Development and Current Practices

The evolution of Chemistry, Manufacturing, and Controls (CMC) in pharma means that it has undergone significant advancements over the decades, driven by technological innovations, regulatory shifts, and the increasing complexities of drug formulations. Initially, CMC focused primarily on fundamental manufacturing processes and quality control. However, as the pharmaceutical landscape has expanded, the demands on what CMC in pharma means have intensified. Today, modern CMC encompasses advanced analytical techniques, robust risk management strategies, and a heightened emphasis on data integrity and traceability.

The emergence of biologics and personalized medicine has further accelerated this evolution, necessitating more stringent controls and comprehensive documentation to ensure safety and efficacy. For instance, the implementation of Analytical Quality by Design (AQbD) frameworks has become essential in drug quality assurance, facilitating proactive management of quality issues throughout the product lifecycle. Furthermore, the adoption of continuous manufacturing methods has enabled seamless scalability, promoting the swift creation of tailored therapies while minimizing waste and energy usage.

Case studies exemplify these advancements:

- Amgen's first digital CMC dossier submission, facilitated by Accumulus Synergy, illustrates how digital transformation is reshaping regulatory processes and expediting global approvals.

- The integration of real-time in-process monitoring technologies provides live data on critical production parameters, thereby reducing batch failures and product variability, which enhances product quality and consistency.

As CMC in pharma means the evolution of practices, the pharmaceutical industry increasingly embraces a lifecycle mindset that emphasizes continuous improvement and the necessity for professionals to blend quantitative rigor with pharmaceutical science. This proactive approach is vital for navigating the complexities of contemporary medication development and ensuring compliance with evolving regulatory landscapes. Moreover, the implementation of green chemistry practices in CMC is gaining momentum, enhancing sustainability and minimizing the environmental impact of manufacturing methods.

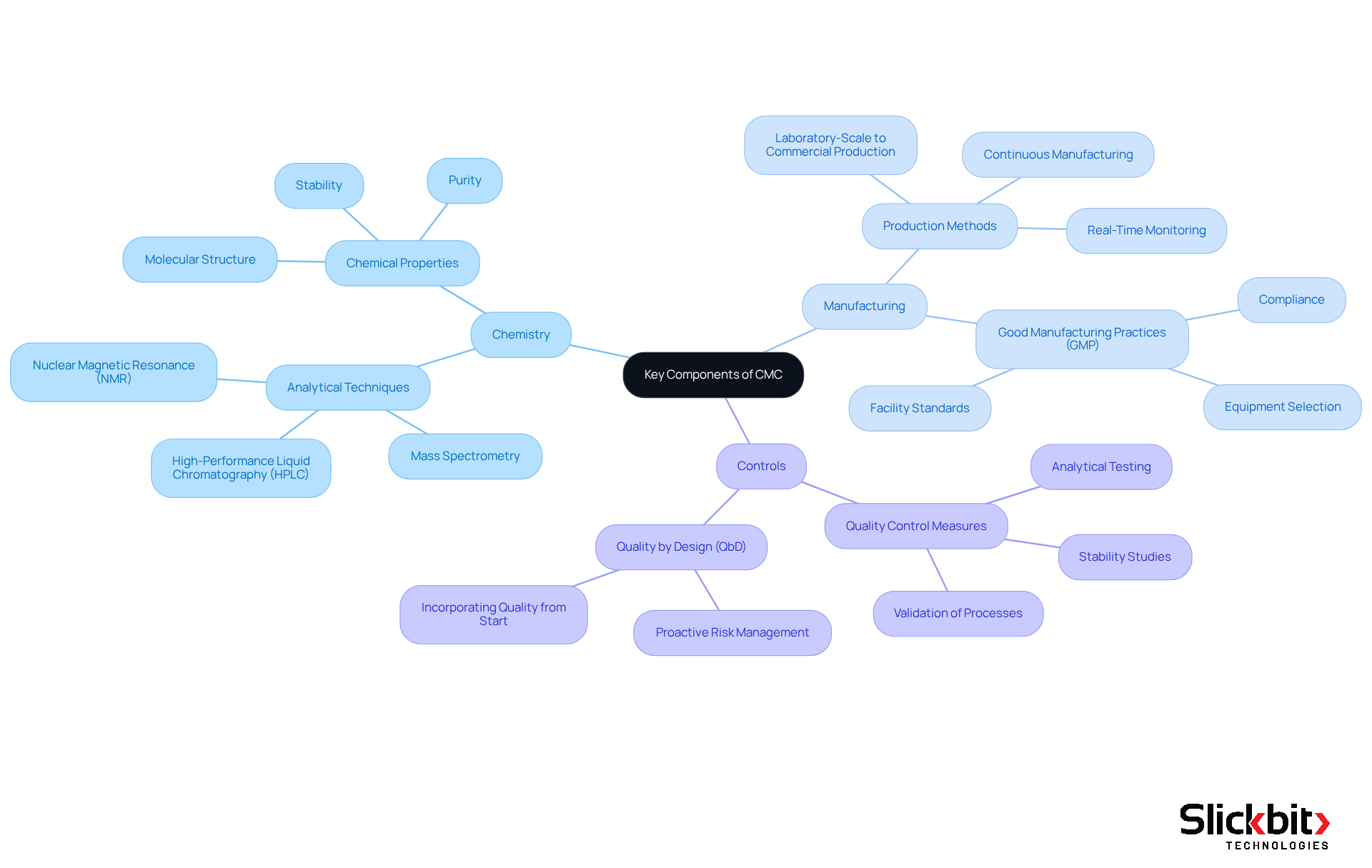

Identify Key Components of CMC: Essential Elements and Their Functions

Key components of CMC include:

-

Chemistry: This encompasses the detailed characterization of the active pharmaceutical ingredient (API), focusing on its chemical properties, stability, and formulation. A comprehensive grasp of the substance's chemistry is crucial for creating efficient production methods. Advanced analytical techniques such as mass spectrometry and high-performance liquid chromatography (HPLC) are employed to ensure batch consistency and product quality.

-

Manufacturing: This encompasses the extensive methods utilized to create the medication, including the vital shift from laboratory-scale to commercial production. Establishing robust manufacturing methods, selecting appropriate equipment, and ensuring facilities comply with Good Manufacturing Practices (GMP) are vital. Furthermore, innovations such as continuous manufacturing and real-time monitoring of operations improve efficiency and consistency in medication production.

-

Controls: Quality control measures are integral to ensuring that the drug meets predefined specifications for identity, strength, purity, and overall quality. This includes rigorous analytical testing, stability studies, and validation of manufacturing processes. Applying a Quality by Design (QbD) strategy enables proactive risk management and guarantees that quality is incorporated into the item from the beginning.

Together, these components ensure that CMC in pharma means the development and manufacturing of pharmaceutical products to the highest standards, ultimately leading to safe and effective medications for patients.

Conclusion

Understanding Chemistry, Manufacturing, and Controls (CMC) is paramount for ensuring the safety, efficacy, and regulatory compliance of pharmaceutical products. CMC serves as the backbone of drug development, guiding the meticulous processes that guarantee every medication meets the highest standards throughout its lifecycle. The increasing complexity of modern pharmaceuticals and the evolving regulatory landscape highlight the necessity for a robust CMC framework that can adapt to new challenges while maintaining quality and safety.

Key insights from the discussion underscore the pivotal role CMC plays in the pharmaceutical industry. From the detailed characterization of active pharmaceutical ingredients to the establishment of rigorous manufacturing methods and quality controls, each element of CMC is essential for successful drug development. The FDA's initiatives, such as the Chemistry, Manufacturing, and Controls Development and Readiness Pilot, further emphasize the importance of timely and comprehensive CMC documentation to avert delays in the approval process. Additionally, the evolution of CMC practices, driven by technological advancements and the emergence of personalized medicine, showcases the industry's commitment to continuous improvement and innovation.

Ultimately, the significance of CMC in pharmaceuticals cannot be overstated. It transcends being merely a regulatory requirement; it is a fundamental aspect that ensures medications are produced safely and effectively. As the industry navigates complex challenges, embracing robust CMC practices is essential for fostering innovation and enhancing patient access to new therapies. Pharmaceutical companies are urged to invest in training, adopt advanced technologies, and prioritize CMC from the earliest stages of development to pave the way for future successes in drug manufacturing and regulatory compliance.

Frequently Asked Questions

What does CMC stand for in the pharmaceutical industry?

CMC stands for Chemistry, Manufacturing, and Controls, which refers to the essential procedures and documentation required for the development of pharmaceutical products.

Why is CMC important in pharma?

CMC is crucial for ensuring that medications are safe, effective, and consistently produced to meet rigorous specifications throughout the medicine development lifecycle.

What does the CMC framework include?

The CMC framework details the chemical characteristics of the medication, the manufacturing processes utilized, and the controls established to ensure quality and regulatory compliance.

What is the FDA's CDRP initiative?

The FDA's Chemistry, Manufacturing, and Controls Development and Readiness Pilot (CDRP) aims to expedite CMC development for investigational new drug applications (INDs) with accelerated clinical timelines.

How does the CDRP program benefit sponsors?

The CDRP program encourages sponsors to submit comprehensive CMC development plans and fosters collaboration with the FDA for product-specific advice, ultimately improving patient access to innovative therapies.

How can technology assist in CMC processes?

AI-driven Regulatory Intelligence tools, such as Slickbit's Lumino, can enhance the CMC workflow by providing accurate answers from FDA and global guidance documents and automating the removal of personally identifiable information (PII) and protected health information (PHI) from documents.

What is the role of Grace R. Graham regarding CMC readiness?

Grace R. Graham, Deputy Commissioner for Policy, Legislation, and International Affairs, emphasizes that successfully expediting CMC readiness may require additional interactions with the FDA during product development.