Overview

The primary distinction between Quality Assurance (QA) and Quality Control (QC) in the pharmaceutical sector centers on their respective focuses. QA is inherently process-oriented, designed to prevent defects from occurring, while QC is product-oriented, concentrating on identifying flaws in the final output. This article elucidates this critical difference by illustrating how QA establishes comprehensive management systems and standards throughout the product lifecycle. In contrast, QC employs rigorous testing and inspection methods to ensure that products adhere to these established standards prior to reaching consumers. By understanding these roles, stakeholders can better appreciate the importance of both QA and QC in delivering safe and effective pharmaceutical products.

Introduction

Understanding the nuances between Quality Assurance (QA) and Quality Control (QC) is essential in the pharmaceutical industry, where the stakes are high and the margin for error is razor-thin. QA encompasses a broad, systematic approach aimed at maintaining excellence throughout the product lifecycle. In contrast, QC zeroes in on the rigorous testing and inspection of final products to ensure they meet stringent standards.

As regulatory demands evolve and the complexity of pharmaceutical processes increases, organizations face the critical challenge of effectively integrating these two components to enhance safety and efficacy. This article delves into the key differences, roles, and the vital importance of both QA and QC in achieving compliance and fostering a culture of quality in the ever-changing landscape of pharmaceuticals.

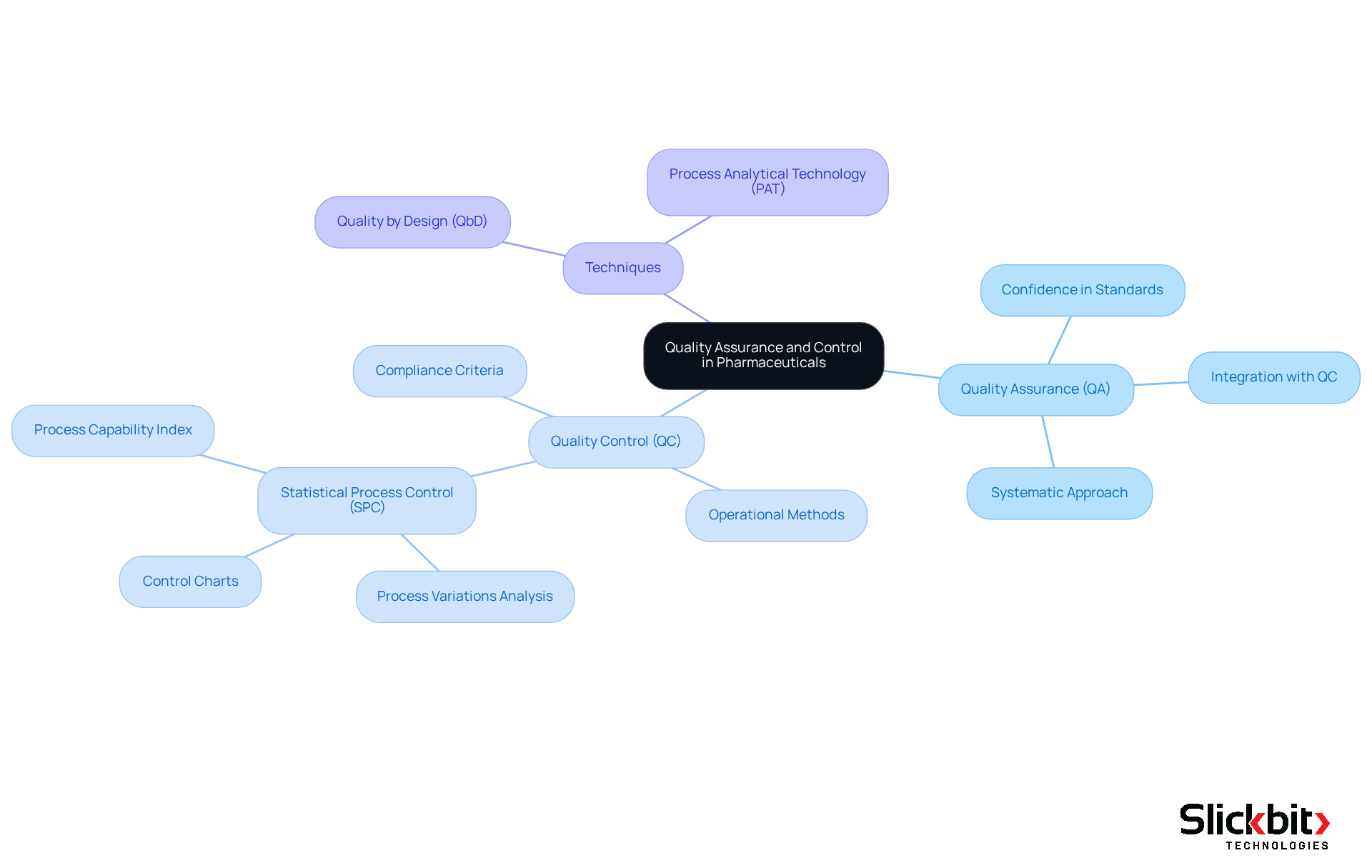

Define Quality Assurance and Quality Control in Pharmaceuticals

Quality Assurance (QA) in pharmaceuticals represents a systematic approach to ensuring excellence throughout the entire development and manufacturing lifecycle. This involves all scheduled and organized activities within the assurance system, intended to instill confidence that products will meet established standards. In contrast, the difference between QA and QC in pharma is that Quality Control (QC) acts as a crucial subset of QA, specifically focusing on the operational methods and activities that ensure adherence to compliance criteria. QC entails rigorous testing of samples from production batches to ensure they meet specified criteria prior to market release.

Understanding the difference between QA and QC in pharma is vital for the integration of QA and QC to ensure the safety and efficacy of pharmaceutical products. Recent developments underscore the increasing necessity for enhanced monitoring procedures, driven by regulatory bodies and industry benchmarks. Statistical Process Control (SPC) has emerged as a key technique for analyzing variations in manufacturing processes, thereby elevating product standards and reducing defects. Companies employing SPC have reported significant decreases in variability, which has led to improved overall product standards and reduced rework costs.

Moreover, the adoption of principles such as Quality by Design (QbD) and Process Analytical Technology (PAT) is revolutionizing QC practices, emphasizing proactive management of standards over reactive measures. These trends highlight the importance of recognizing the difference between QA and QC in pharma, as organizations with advanced quality management systems experience fewer recalls and lower rejection rates, ultimately enhancing their competitive edge in the market.

With the integration of AI-powered Regulatory Intelligence solutions, such as those provided by Slickbit, pharmaceutical teams can access accurate, traceable answers from FDA and global guidance documents, thereby augmenting their QA processes. Additionally, tools like Vault Redact automate the identification and removal of Personally Identifiable Information (PII) and Protected Health Information (PHI) from documents, ensuring compliance and protecting sensitive information. Collectively, these solutions strengthen the QA and QC framework, ensuring the safety and effectiveness of medical products.

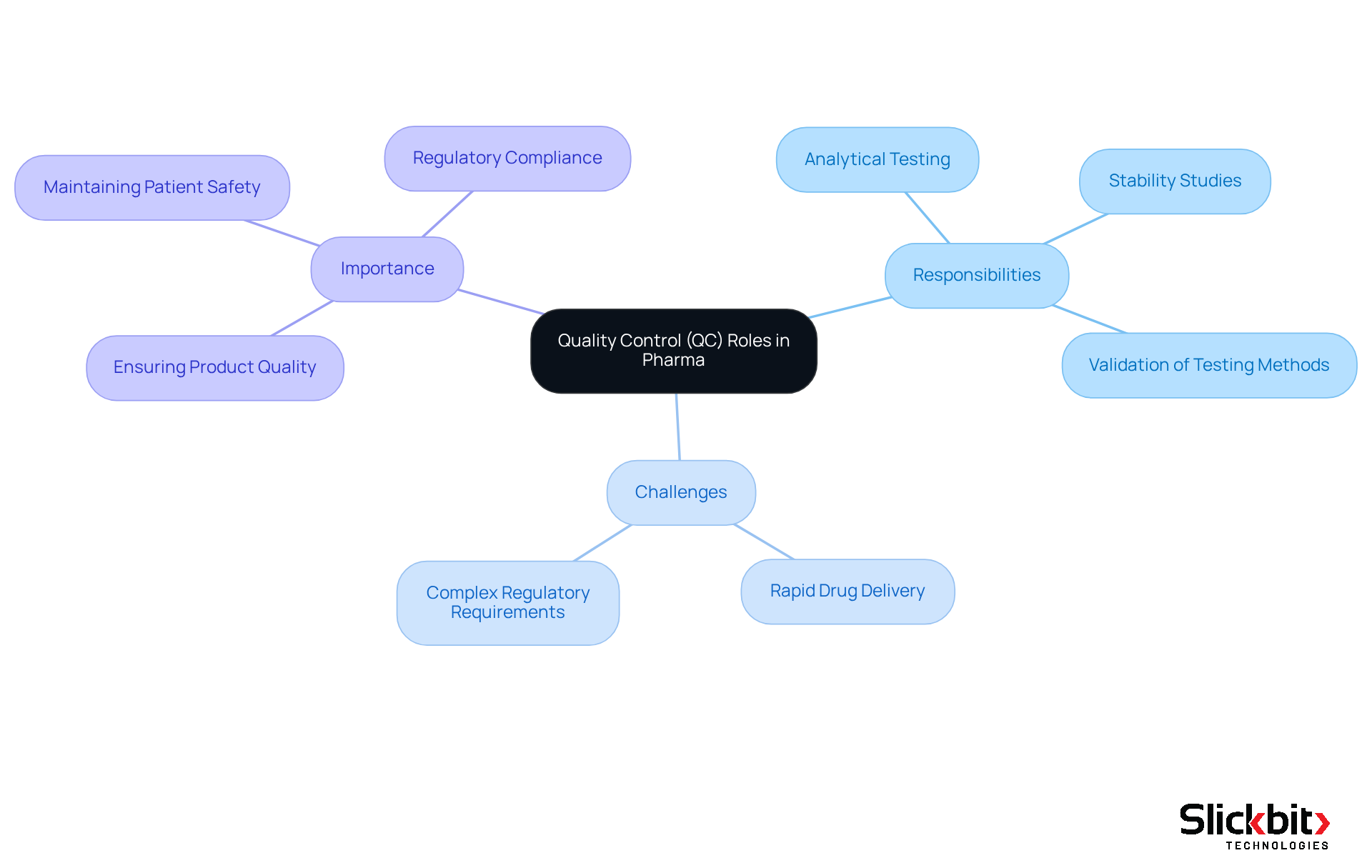

Explore the Roles and Responsibilities of QA and QC

Quality Control (QC) teams are indispensable in the pharmaceutical sector, focusing on the rigorous testing and inspection of raw materials, in-process materials, and finished products. Their responsibilities encompass a range of critical functions, including:

- Analytical testing

- Stability studies

- Validation of testing methods

All aimed at ensuring that products meet established standards. For instance, QC teams conduct stability testing to evaluate how a drug's properties change under varying environmental conditions, thereby guaranteeing safety and efficacy throughout its shelf life.

In addition to testing, QC teams are responsible for implementing systematic control practices that help identify defects before products reach consumers. This proactive approach is crucial for preserving the integrity of medical products, as it facilitates the detection of variances through thorough inspection and testing. Techniques like in-process control (IPQC) monitor vital process parameters during production, ensuring batch consistency and minimizing the risk of reprocessing.

Despite their essential role, QC teams face numerous challenges in today's medical landscape. These challenges include:

- The demand for rapid drug delivery, which can pressure standard procedures

- The increasing complexity of regulatory requirements

Furthermore, the integration of advanced statistical methods and technologies into QC practices is vital for improving efficiency and accuracy in testing.

Ultimately, understanding the difference between QA and QC in pharma is crucial for the collaboration between Quality Assurance (QA) and Quality Control (QC) to ensure that products not only comply with regulatory standards but also meet the high expectations of safety and effectiveness. Both processes aim to achieve customer satisfaction and uphold the organization’s reputation. By fostering a culture of excellence and continuous improvement, QC teams play a pivotal role in the overall success of healthcare operations.

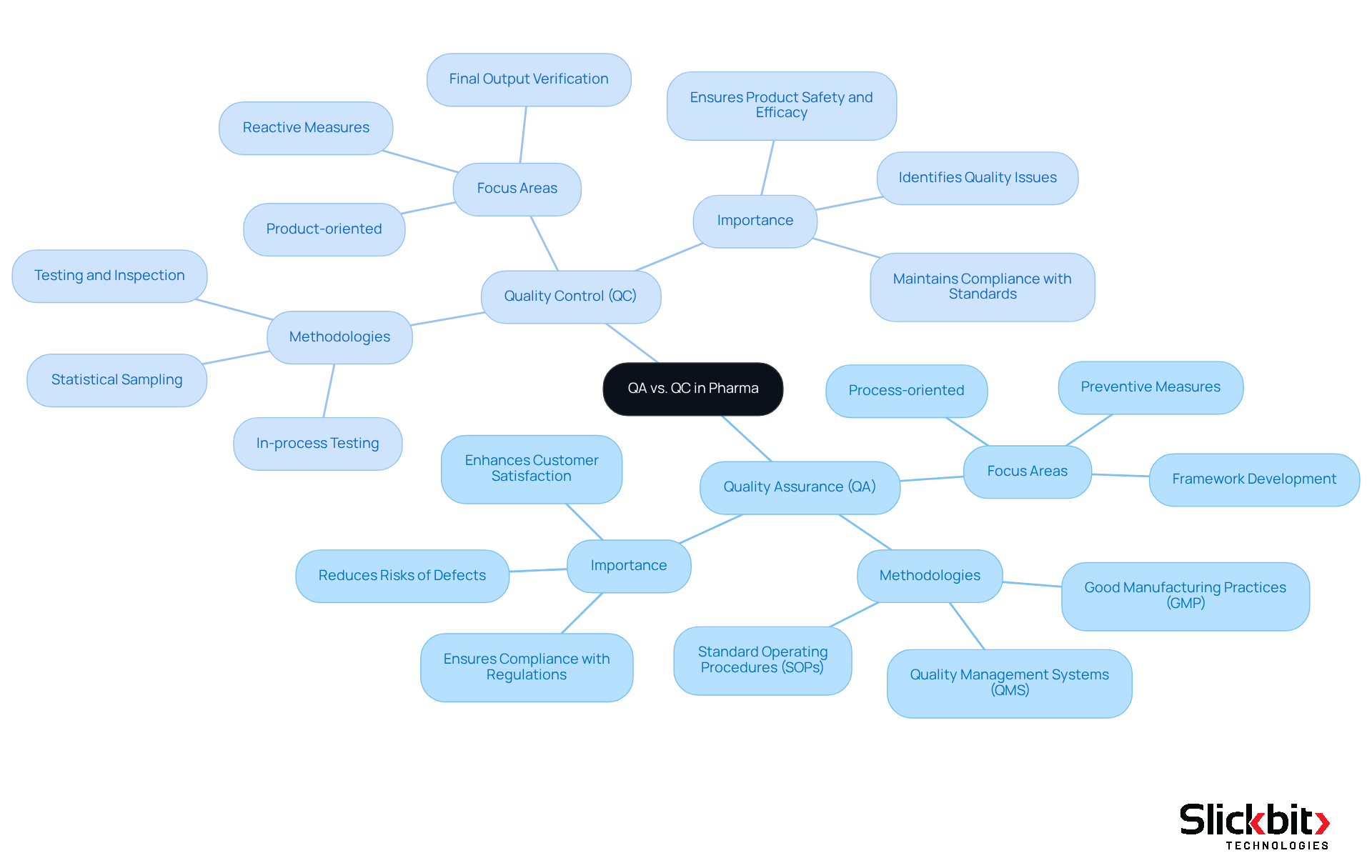

Identify Key Differences Between Quality Assurance and Quality Control

Understanding the difference between QA and QC in pharma is fundamental, primarily revolving around their focus and methodologies. QA is fundamentally process-focused, emphasizing the creation and upkeep of systematic procedures and management systems aimed at preventing defects from the outset. This proactive method encompasses the development of comprehensive frameworks, such as Standard Operating Procedures (SOPs) and Good Manufacturing Practices (GMP), which are crucial for ensuring that excellence is integrated throughout the lifecycle of the product. QA activities occur throughout the product lifecycle, enhancing customer satisfaction by ensuring offerings meet or exceed anticipated standards.

In contrast, QC is product-oriented, concentrating on the identification of flaws in the final output through rigorous testing and inspection. This responsive approach is essential for confirming that products comply with established standards before they reach consumers. QC employs various methods, including statistical sampling and in-process testing, to ensure adherence to the standards set by QA. Documentation in QC is vital for maintaining detailed records of activities, analyses, and specifications, ensuring thoroughness in the quality control processes.

Current industry guidelines underscore the significance of both QA and QC in ensuring safety and effectiveness. Regulatory bodies, such as the FDA and EMA, enforce stringent compliance requirements that necessitate a robust QA framework to mitigate risks and enhance management controls. Effective Quality Risk Management (QRM) practices are essential for identifying and addressing potential risks throughout the manufacturing process, thereby ensuring product safety and efficacy.

Expert analysis emphasizes the difference between QA and QC in pharma, highlighting that QA establishes the standards and guidelines essential for assurance, while QC serves as the critical checkpoint that confirms compliance with these standards. This symbiotic relationship between QA and QC is vital for companies in the healthcare sector aiming to enhance operational efficiency, reduce waste, and ultimately ensure patient safety. The drug management market is projected to expand from $6.95 billion to $9.69 billion by 2027, highlighting the growing importance of strong QA and QC practices. By understanding and applying both process-oriented and product-oriented management strategies, organizations can gain a competitive advantage in a rapidly evolving market.

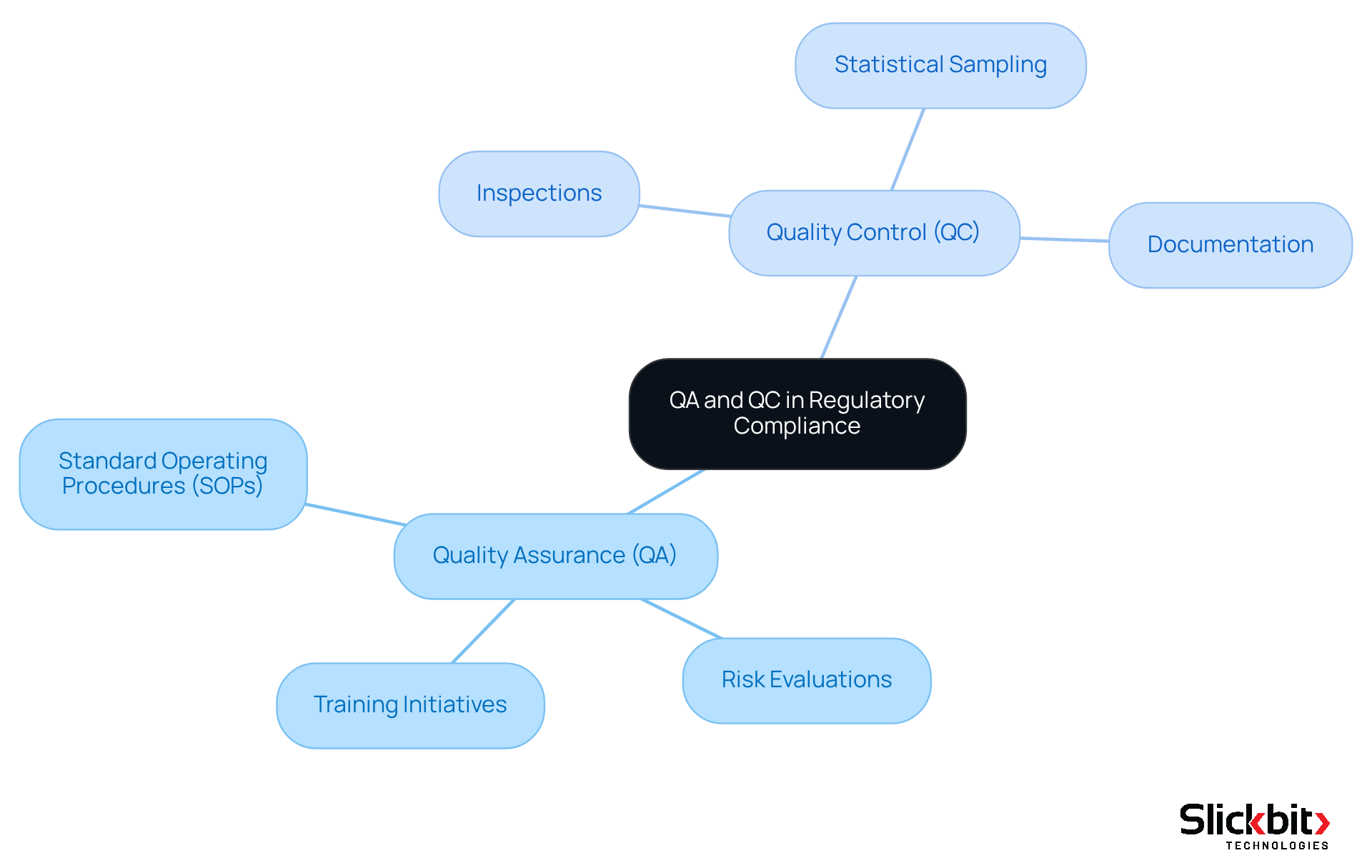

Understand the Importance of QA and QC in Regulatory Compliance

Understanding the difference between QA and QC in pharma is crucial, as both are pivotal components of regulatory compliance within the pharmaceutical industry, mandated by agencies such as the FDA and EMA. These regulatory bodies impose stringent safety standards to guarantee that pharmaceutical products are both safe and effective for public consumption. The processes involved in QA are designed to establish and uphold a comprehensive management system that aligns with these regulatory requirements. This includes:

- The formulation of Standard Operating Procedures (SOPs)

- Conducting risk evaluations

- Implementing training initiatives to ensure that excellence is woven throughout the manufacturing process

In contrast, the difference between QA and QC in pharma highlights that QC activities concentrate on the testing and verification of products before they reach the market. This involves:

- Rigorous inspections and evaluations at various stages of production to confirm compliance with established standards

- Effective QC practices that leverage statistical sampling techniques

- Meticulous documentation to detect and address any deviations from quality expectations, thereby mitigating potential risks

The ramifications of non-compliance can be dire, resulting in product recalls, legal consequences, and substantial damage to a company's reputation. Consequently, it is imperative for organizations to prioritize robust QA and QC practices to understand the difference between QA and QC in pharma, uphold compliance, and ensure patient safety. Successful implementations of QA and QC demonstrate that adherence to FDA and EMA standards not only diminishes risks but also enhances operational efficiency and accelerates time-to-market for medicinal products. By cultivating a culture of quality, pharmaceutical companies can adeptly navigate the complexities of regulatory compliance while delivering safe and effective products to the marketplace.

Conclusion

Understanding the distinction between Quality Assurance (QA) and Quality Control (QC) in the pharmaceutical industry is essential for ensuring the safety and efficacy of medical products. QA focuses on systematic processes that prevent defects throughout the entire product lifecycle, while QC is centered on rigorous testing and inspection of finished products to confirm compliance with established standards. This relationship between QA and QC not only enhances product quality but also fosters a culture of continuous improvement within organizations.

The article highlights several key points, including:

- The vital roles that both QA and QC play in regulatory compliance.

- The integration of advanced methodologies like Statistical Process Control and Quality by Design.

- The importance of thorough documentation and inspection practices.

By employing these strategies, pharmaceutical companies can mitigate risks, reduce waste, and ultimately deliver safer and more effective products to the market.

In conclusion, the implications of understanding the difference between QA and QC extend beyond compliance; they are foundational to maintaining a competitive edge in a rapidly evolving industry. Organizations that prioritize robust QA and QC practices not only ensure adherence to regulatory standards but also enhance their operational efficiency, thereby safeguarding public health. Embracing a culture of quality can empower pharmaceutical companies to navigate regulatory challenges effectively while contributing to the overall trust and safety of the healthcare system.

Frequently Asked Questions

What is Quality Assurance (QA) in pharmaceuticals?

Quality Assurance (QA) in pharmaceuticals is a systematic approach to ensuring excellence throughout the entire development and manufacturing lifecycle, involving organized activities intended to instill confidence that products will meet established standards.

How does Quality Control (QC) differ from Quality Assurance (QA) in pharmaceuticals?

Quality Control (QC) is a subset of QA that focuses specifically on the operational methods and activities ensuring compliance with criteria. QC involves rigorous testing of samples from production batches to ensure they meet specified criteria prior to market release.

Why is it important to understand the difference between QA and QC in pharmaceuticals?

Understanding the difference between QA and QC is vital for integrating both processes to ensure the safety and efficacy of pharmaceutical products.

What role does Statistical Process Control (SPC) play in pharmaceuticals?

Statistical Process Control (SPC) is a key technique for analyzing variations in manufacturing processes, helping to elevate product standards and reduce defects. Companies using SPC have reported significant decreases in variability, leading to improved overall product standards and reduced rework costs.

What are Quality by Design (QbD) and Process Analytical Technology (PAT)?

Quality by Design (QbD) and Process Analytical Technology (PAT) are principles that revolutionize QC practices by emphasizing proactive management of standards rather than reactive measures.

How do advanced quality management systems benefit pharmaceutical organizations?

Organizations with advanced quality management systems experience fewer recalls and lower rejection rates, ultimately enhancing their competitive edge in the market.

What is the impact of AI-powered Regulatory Intelligence solutions on QA processes?

AI-powered Regulatory Intelligence solutions, like those provided by Slickbit, enable pharmaceutical teams to access accurate, traceable answers from FDA and global guidance documents, thereby augmenting their QA processes.

How does Vault Redact contribute to compliance in pharmaceuticals?

Vault Redact automates the identification and removal of Personally Identifiable Information (PII) and Protected Health Information (PHI) from documents, ensuring compliance and protecting sensitive information.

What is the overall goal of integrating QA and QC in pharmaceuticals?

The overall goal of integrating QA and QC is to strengthen the framework that ensures the safety and effectiveness of medical products.