Overview

The article elucidates the definition of Chemistry, Manufacturing, and Controls (CMC) within the pharmaceutical sector, underscoring its essential components and its critical role in maintaining product integrity and ensuring regulatory compliance.

Effective CMC practices are not merely beneficial; they are imperative for successful drug development and market entry. This includes:

- Thorough documentation

- Robust quality management

- Proactive risk mitigation

Case studies illustrate that insufficient CMC documentation can result in substantial delays or even rejection of drug applications, highlighting the necessity for meticulous attention to these practices.

Introduction

Understanding the complexities of pharmaceutical development demands an in-depth exploration of the critical framework known as Chemistry, Manufacturing, and Controls (CMC). This vital component guarantees that drugs are not only effective but also comply with the stringent safety standards established by regulatory bodies. As the drug development landscape evolves—especially with the emergence of biologics and advanced therapies—the challenge becomes mastering CMC practices that can adapt to these shifts.

Consequently, how can pharmaceutical companies effectively navigate this intricate web of requirements to ensure successful market entry and safeguard patient safety?

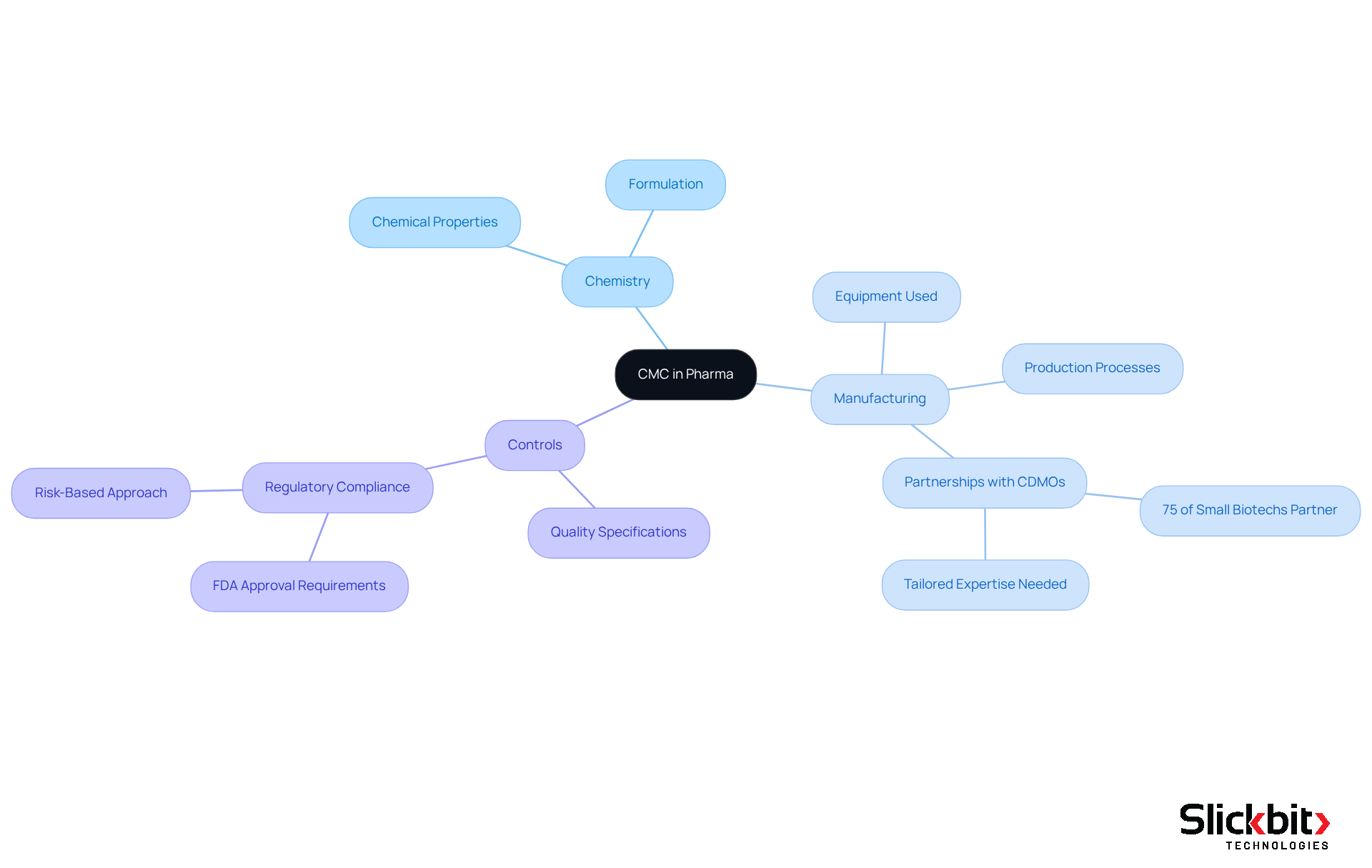

Define CMC: Core Components and Significance in Pharma

The cmc definition pharma constitutes a vital framework of activities and documentation essential for maintaining the integrity and consistency of pharmaceutical products throughout their lifecycle. It encompasses three principal components:

- Chemistry, which focuses on the drug's chemical properties and formulation;

- Manufacturing, detailing the processes and equipment employed in production;

- Controls, which ensure adherence to standards and quality specifications.

The importance of CMC definition pharma is highlighted by its critical role in drug development, ensuring that products are not only safe and effective but also comply with stringent regulatory standards.

In 2023, the cell and gene therapy sector witnessed the initiation of over 90 new trials, highlighting the increasing complexity and oversight within this domain. The cmc definition pharma highlights that effective CMC practices are indispensable, as illustrated by case studies demonstrating that the early integration of CMC strategies substantially mitigated risks tied to compressed timelines. For example, developers who partnered with experienced Contract Development and Manufacturing Organizations (CDMOs) effectively managed compliance discussions, thereby accelerating their path to commercialization.

Industry leaders stress the necessity of robust early CMC definition pharma planning. Dr. Clare Blue, a senior CMC translation consultant, emphasizes that establishing platform processes and leveraging advanced technologies such as AI and Process Analytical Technology (PAT) are crucial for averting issues during FDA approval. Moreover, the FDA has indicated that the comprehensive CMC definition pharma requirements are vital for strong filing submissions, particularly under tight deadlines.

As the drug development landscape evolves in 2025, the relevance of CMC continues to escalate, with an urgent need for specialized expertise and adaptable pricing models to support startups and small biotechs. The early incorporation of the cmc definition pharma in the development process not only enhances product standards but also ensures regulatory compliance, ultimately facilitating successful market entry.

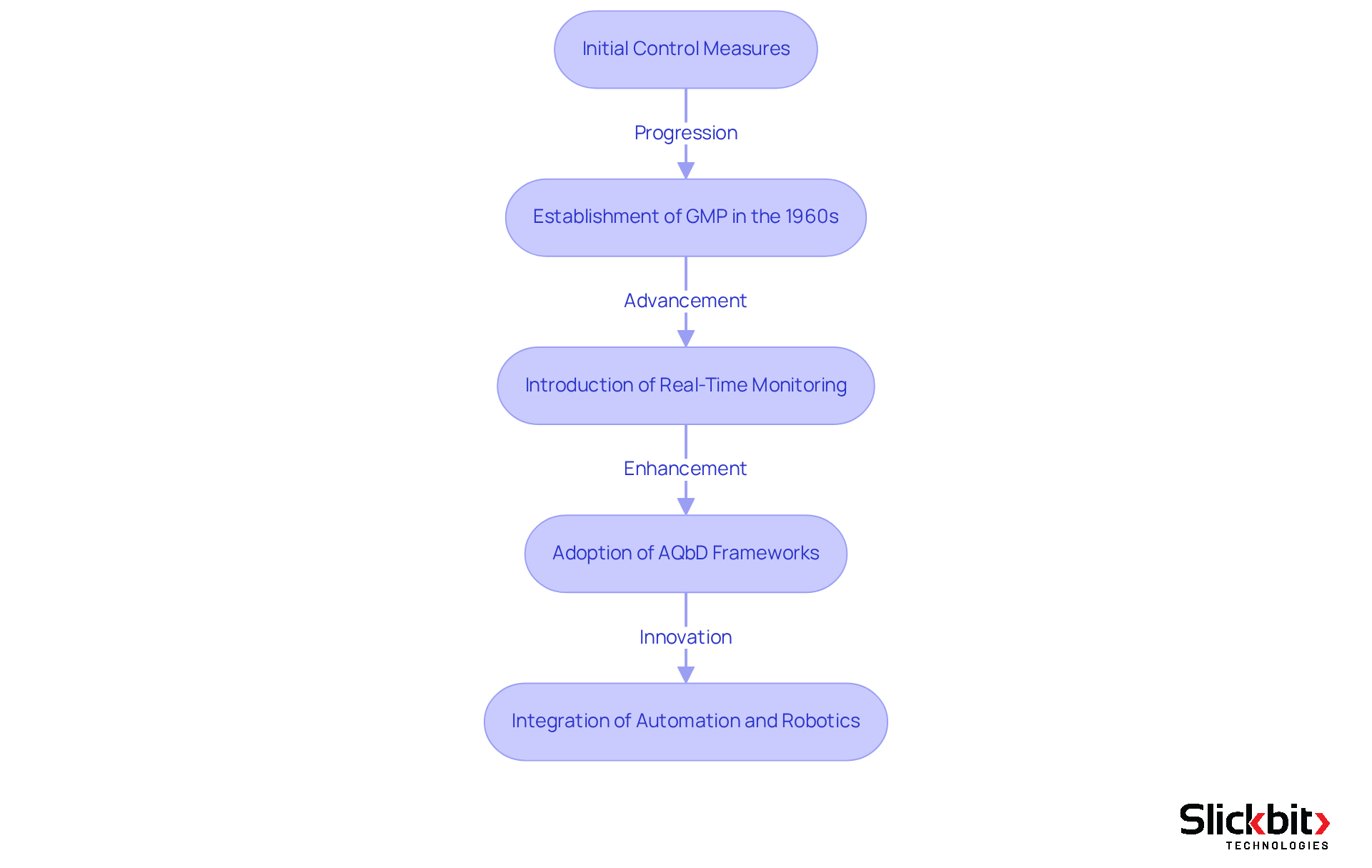

Trace the Evolution of CMC in Pharmaceutical Development

The evolution of the CMC definition pharma in pharmaceutical development has undergone significant transformation since the inception of drug manufacturing. Initially, fundamental control measures were established; however, as regulatory frameworks became stricter, CMC processes expanded to encompass comprehensive documentation and stringent testing protocols. The introduction of Good Manufacturing Practices (GMP) in the 1960s marked a pivotal moment, underscoring the necessity for thorough assurance throughout the manufacturing lifecycle. This transformation not only enhanced safety and effectiveness but also established a foundation for uniform standards.

In recent years, CMC practices have become increasingly sophisticated, leveraging advanced technologies such as real-time monitoring and predictive analytics. Ongoing monitoring mitigates the risks of batch failures and variability in products, resulting in higher yields and reduced costs. For example, continuous manufacturing processes facilitate seamless scalability between large and small production batches, significantly lowering energy consumption and waste compared to traditional batch methods.

Case studies exemplify the impact of GMP on CMC practices. The adoption of Analytical Quality by Design (AQbD) frameworks, for instance, has empowered companies to proactively manage attribute standards, thereby reducing production downtime and enhancing flexibility in manufacturing. This is evident in the case study on Advanced Analytics and Real-Time Monitoring in Drug Development, which highlights how these technologies elevate product standards and consistency. Moreover, the integration of automation and robotics has bolstered efficiency and minimized human error, which is crucial for upholding high standards in drug development. Automation and robotics notably enhance efficiency in small-batch production, further reducing the potential for human error.

As policy changes continue to influence the pharmaceutical development landscape, the evolution of the CMC definition pharma remains essential. Companies that invest in digital infrastructure and sustainable practices—such as substituting petrochemical-based solvents with bio-based alternatives—are better positioned to navigate these shifts, ensuring compliance and fostering innovation within the ever-evolving biopharmaceutical industry.

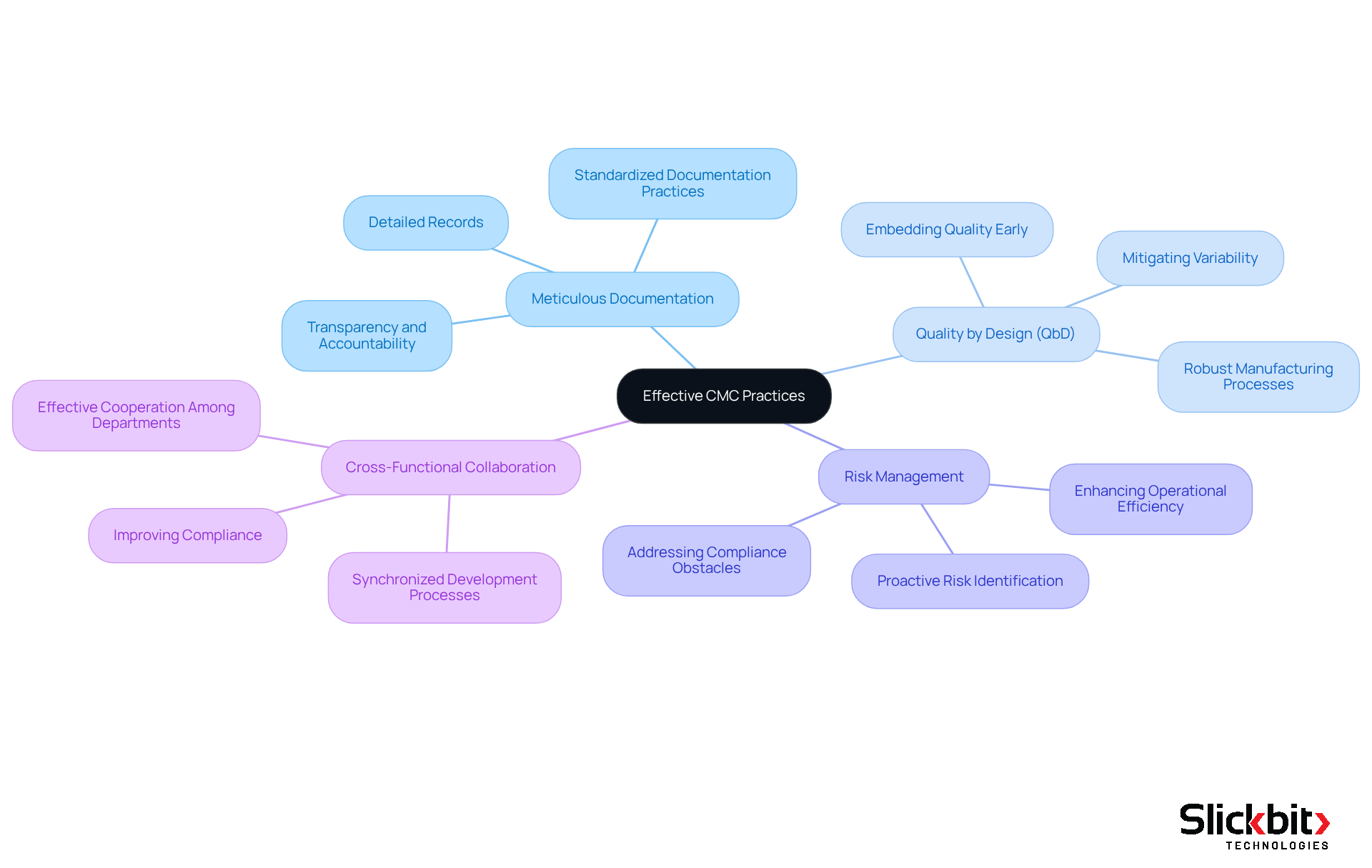

Identify Key Characteristics of Effective CMC Practices

The CMC definition in pharma emphasizes effective practices characterized by meticulous documentation, stringent control measures, and a proactive approach to regulatory compliance. Comprehensive documentation is essential; maintaining detailed records of all processes, materials, and testing results ensures transparency and accountability throughout the product lifecycle. Furthermore, the Quality by Design (QbD) approach emphasizes embedding excellence into the product from the early development phases, rather than relying solely on final testing. The widespread adoption of QbD principles has become a standard in the industry, enhancing the robustness of manufacturing processes and mitigating variability, which is crucial for maintaining quality.

In addition, risk management plays a vital role in proactively identifying and addressing potential risks throughout the development process. This focus on risk management not only ensures product safety and efficacy but also enhances operational efficiency and reduces compliance obstacles for organizations. Cross-functional collaboration is another key element; the CMC definition in pharma necessitates effective cooperation among various departments, including R&D, manufacturing, and compliance affairs. This alignment is essential for maintaining compliance and ensuring that all aspects of the development process are synchronized.

Integrating these practices simplifies the CMC definition in pharma process and significantly influences the approval process by oversight bodies such as the FDA, ensuring that products adhere to the highest standards of safety and efficacy. Recent advancements underscore the importance of robust statistical methods in CMC, particularly in designing and evaluating stability studies that assess how environmental factors affect medication potency and shelf life. Consequently, by utilizing QbD principles and adhering to best practices, organizations can enhance their CMC strategies, ultimately leading to successful submissions and improved patient outcomes.

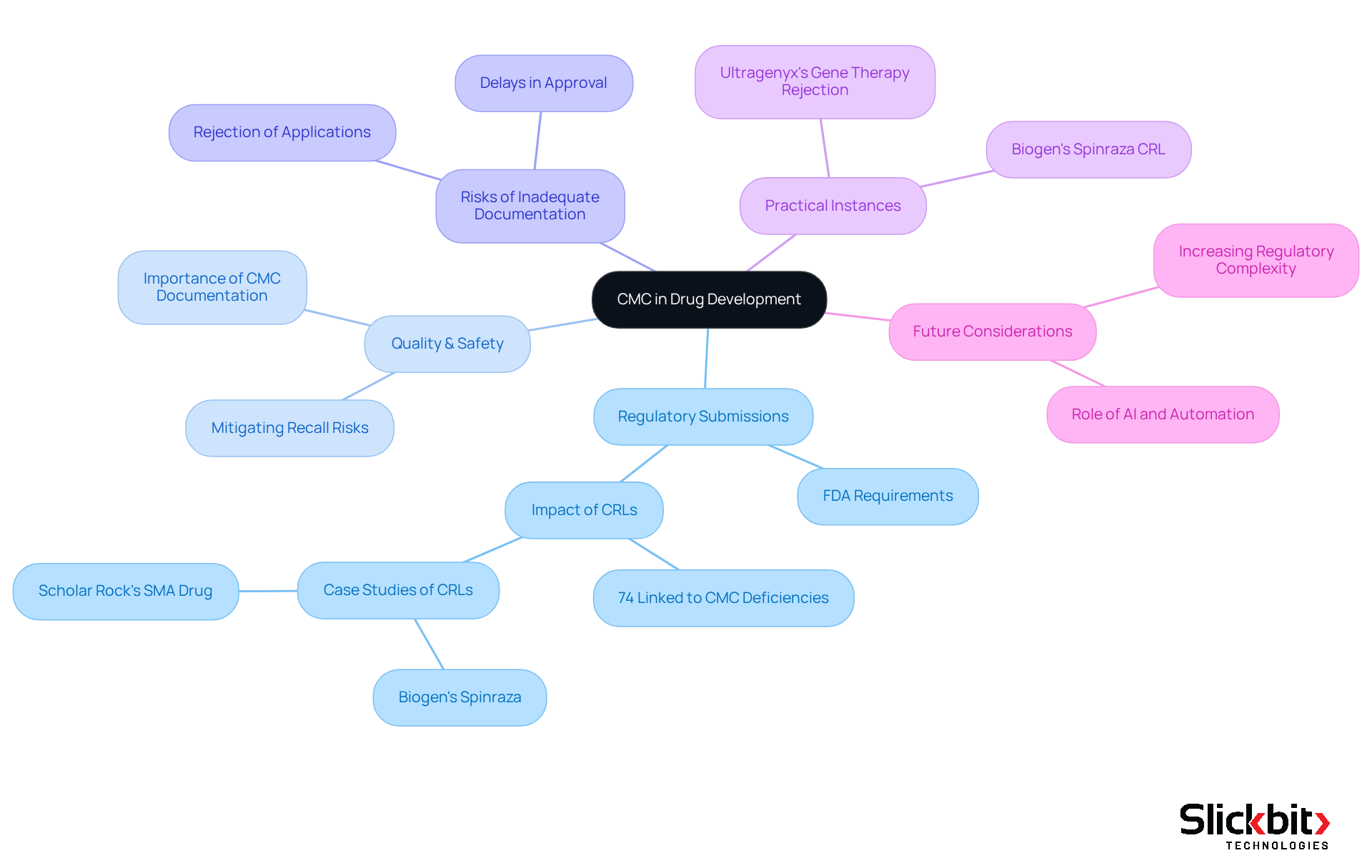

Examine the Practical Implications of CMC in Drug Development

The implications of the CMC definition pharma in drug development are significant, influencing every phase from formulation to market entry. The CMC definition pharma emphasizes that CMC documentation is vital for regulatory submissions, as agencies such as the FDA require thorough information concerning chemistry, manufacturing processes, and controls. Inadequate CMC documentation may lead to significant delays or outright rejection of drug applications; indeed, 74% of Complete Response Letters (CRLs) issued by the FDA from 2020 to 2024 were linked to deficiencies in standards and manufacturing. Effective practices that align with the CMC definition pharma not only enhance the quality and safety of pharmaceutical products but also mitigate the risk of recalls, thereby safeguarding patient health.

As the pharmaceutical landscape evolves, particularly with the increasing prevalence of biologics and personalized medicine, the necessity for robust practices aligned with the CMC definition pharma will only intensify. Practical instances, such as Biogen's Spinraza encountering a CRL because of CMC-related concerns and Scholar Rock's SMA medication being denied due to production issues, highlight the essential importance of comprehensive CMC definition pharma documentation in maneuvering through the approval landscape and attaining successful drug authorizations. Furthermore, as highlighted by Clare Blue, the establishment of platform processes and the utilization of AI will be key to preventing CMC issues, reflecting the growing complexity of regulatory requirements for advanced therapies.

Conclusion

The CMC definition in pharmaceuticals is a cornerstone for ensuring the safety, efficacy, and regulatory compliance of drug products throughout their lifecycle. By focusing on the critical components of chemistry, manufacturing, and controls, the CMC framework not only safeguards product integrity but also enhances the overall quality of pharmaceutical development processes.

Key insights illustrate the evolution of CMC practices, emphasizing the importance of:

- Meticulous documentation

- Risk management

- Cross-functional collaboration

As the pharmaceutical landscape advances, particularly with the rise of biologics and personalized medicine, the integration of advanced technologies and proactive CMC strategies becomes essential. Companies that prioritize these practices are better equipped to navigate regulatory complexities and accelerate their path to market.

Ultimately, the significance of the CMC definition in drug development cannot be overstated. As the industry continues to evolve, embracing robust CMC practices will enhance product standards, protect patient health, and ensure successful market entry. The call to action is clear: stakeholders must invest in effective CMC strategies to foster innovation and compliance in an increasingly competitive and regulated environment.

Frequently Asked Questions

What does CMC stand for in the pharmaceutical context?

CMC stands for Chemistry, Manufacturing, and Controls, which is a framework of activities and documentation essential for maintaining the integrity and consistency of pharmaceutical products throughout their lifecycle.

What are the three principal components of CMC?

The three principal components of CMC are Chemistry, which focuses on the drug's chemical properties and formulation; Manufacturing, which details the processes and equipment used in production; and Controls, which ensure adherence to standards and quality specifications.

Why is CMC important in drug development?

CMC is critical in drug development as it ensures that pharmaceutical products are safe, effective, and compliant with stringent regulatory standards.

What recent trends have been observed in the cell and gene therapy sector related to CMC?

In 2023, the cell and gene therapy sector saw the initiation of over 90 new trials, highlighting the increasing complexity and oversight within this domain.

How can effective CMC practices impact drug development timelines?

Effective CMC practices can substantially mitigate risks tied to compressed timelines, as demonstrated by case studies where early integration of CMC strategies helped developers manage compliance discussions and accelerate their path to commercialization.

What role does early CMC planning play according to industry leaders?

Industry leaders stress the necessity of robust early CMC planning to establish platform processes and leverage advanced technologies, such as AI and Process Analytical Technology (PAT), to avoid issues during FDA approval.

What does the FDA say about CMC requirements?

The FDA indicates that comprehensive CMC requirements are vital for strong filing submissions, especially under tight deadlines.

How is the relevance of CMC expected to change by 2025?

As the drug development landscape evolves by 2025, the relevance of CMC is expected to escalate, with an urgent need for specialized expertise and adaptable pricing models to support startups and small biotechs.

What benefits does early incorporation of CMC provide in the development process?

Early incorporation of CMC enhances product standards, ensures regulatory compliance, and facilitates successful market entry.