Overview

This article serves as an essential guide for R&D managers aiming to master 21 CFR Part 210, underscoring the critical role of current good manufacturing practices (cGMP) in safeguarding drug safety and quality.

It delineates key compliance requirements, including:

- The establishment of a robust Quality Management System

- Meticulous documentation

- Ongoing personnel training

Furthermore, it advocates for the strategic utilization of technology and resources to effectively bolster compliance efforts. By adhering to these guidelines, R&D managers can ensure that their operations not only meet regulatory standards but also enhance the overall quality of pharmaceutical products.

Introduction

Navigating the complexities of 21 CFR Part 210 is crucial for R&D managers in the pharmaceutical manufacturing sector. This regulation establishes the framework for current good manufacturing practices (cGMP), which are vital for ensuring that drug products are safe, effective, and of high quality.

As compliance requirements evolve and advanced technologies are integrated, the challenge for managers is to implement strategies that not only meet regulatory standards but also drive operational excellence.

This guide provides a comprehensive, step-by-step approach to mastering 21 CFR Part 210, equipping R&D managers with the essential knowledge and tools to thrive in a stringent regulatory environment.

Understand 21 CFR Part 210: Key Definitions and Importance

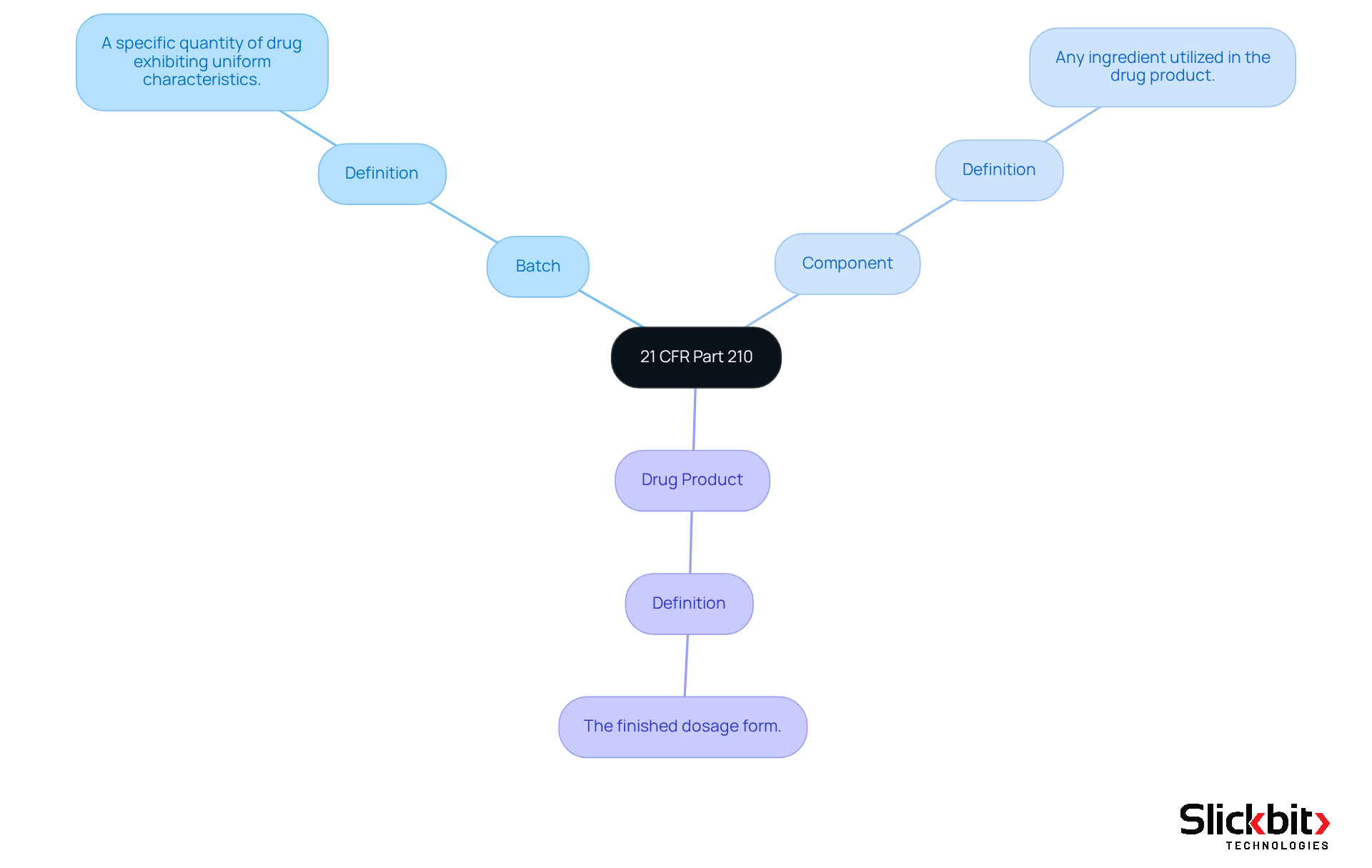

The minimum current good manufacturing practices (cGMP) essential for drug production, processing, packing, or holding are delineated in 21 CFR Part 210. Key definitions are foundational to understanding compliance:

- Batch: A specific quantity of drug exhibiting uniform characteristics.

- Component: Any ingredient utilized in the drug product.

- Drug Product: The finished dosage form.

Grasping these definitions is paramount, as they establish the groundwork for adherence and assurance in pharmaceutical manufacturing. Moreover, leveraging AI technologies, such as those capable of detecting patterns in FDA inspections, can significantly enhance adherence efforts. These technologies provide critical insights into systemic risks and recurring violations. Consequently, strict adherence to the 21 CFR Part 210 regulations guarantees that products are safe, effective, and of high quality, ultimately safeguarding public health.

Identify Compliance Requirements: Navigating the Guidelines of 21 CFR Part 210

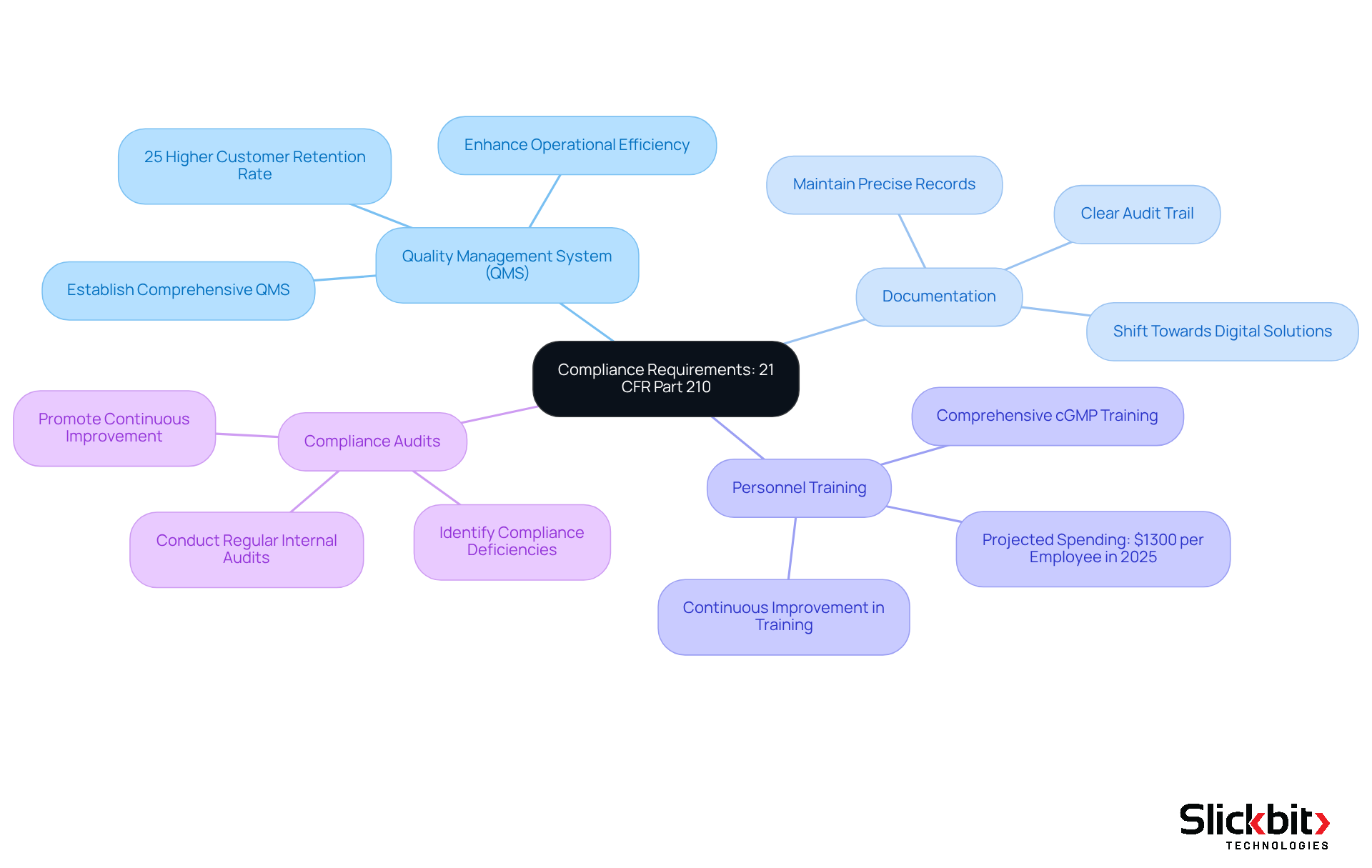

To effectively navigate the compliance requirements of 21 CFR Part 210, R&D managers must prioritize several key areas crucial for operational success:

-

Quality Management System (QMS): Establish a comprehensive QMS that encompasses all aspects of production, including documentation, training, and controls. A well-executed QMS guarantees adherence while also enhancing operational efficiency. Organizations with effective systems report a 25% higher customer retention rate, underscoring the importance of robust quality management.

-

Documentation: It is essential to maintain precise and thorough records, including batch records, testing results, and standard operating procedures (SOPs). Effective documentation practices are vital for compliance, providing a clear audit trail and supporting the integrity of the manufacturing process. Current trends indicate a shift towards digital documentation solutions, which streamline record-keeping and significantly reduce errors.

-

Personnel Training: Ensure that all staff receive comprehensive training on cGMP requirements and their specific responsibilities in upholding these regulations. Continuous improvement in training methodologies is critical, as organizations are expected to invest heavily in employee development. Spending per employee on learning and development is projected to reach nearly $1300 in 2025, highlighting the necessity of ongoing training initiatives.

-

Compliance with 21 CFR Part 210: Conduct regular internal audits to evaluate adherence to both internal procedures and 21 CFR Part 210. These audits serve as a proactive measure to identify potential deficiencies in compliance and promote continuous improvement.

By concentrating on these essential areas, R&D managers can effectively recognize and implement the critical regulatory requirements, ensuring that their organizations not only meet legal standards but also enhance product quality and safety.

Implement Compliance Strategies: Step-by-Step Actions for R&D Managers

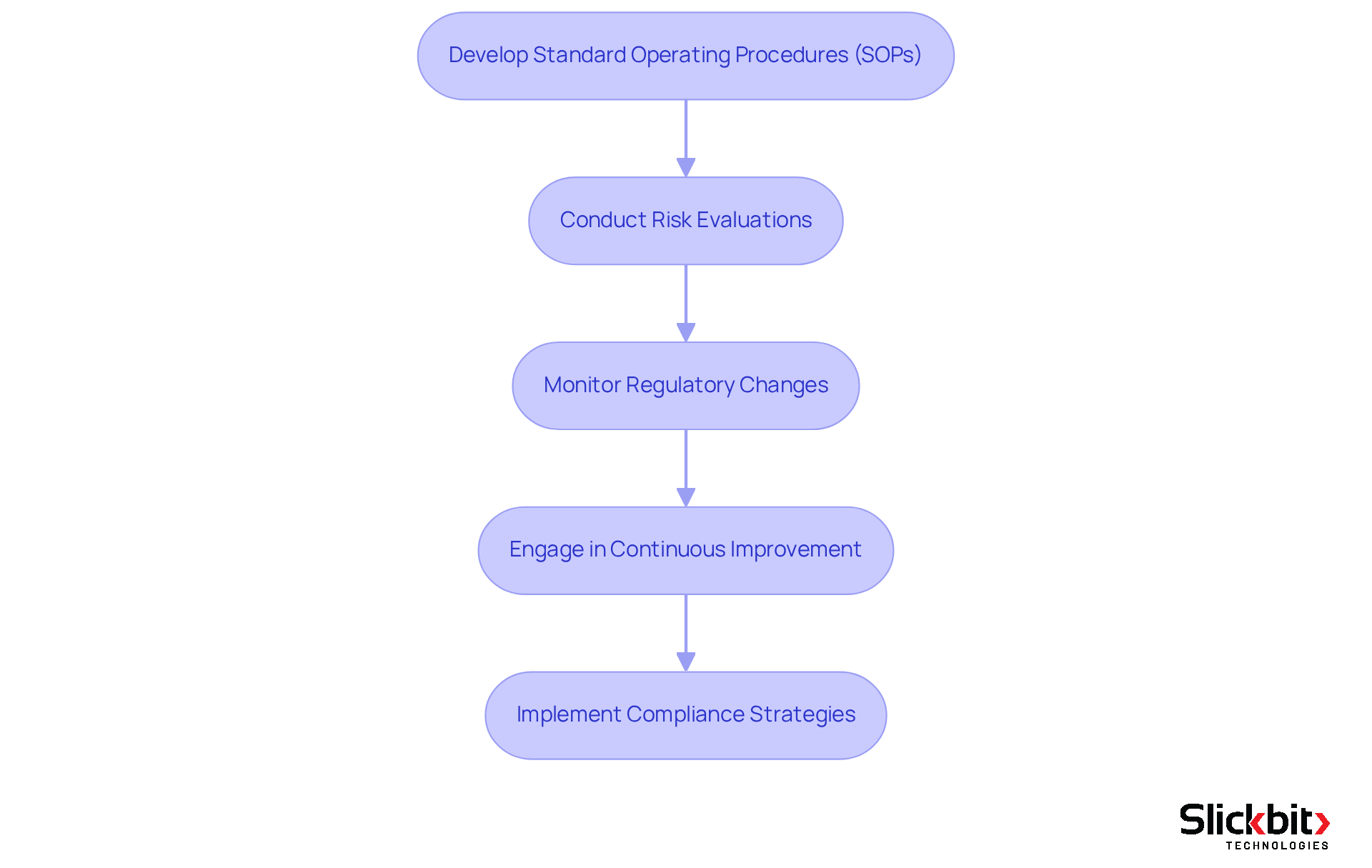

To implement effective compliance strategies, R&D managers must follow a series of essential steps designed to enhance product standards and safety while upholding regulatory integrity.

-

Develop Standard Operating Procedures (SOPs): It is crucial to create detailed SOPs for all production activities, ensuring alignment with current Good Practices in Production (cGMP) standards. Each SOP should be clear, concise, and structured to facilitate consistent execution, incorporating essential components such as title, purpose, scope, and detailed procedures.

-

Conduct Risk Evaluations: Regular assessments of hazards linked to manufacturing methods are vital. Implement robust risk assessment strategies that encompass identifying potential hazards, analyzing their impact, and establishing controls to mitigate these risks. Involving cross-functional teams in this process can significantly enhance the accuracy and effectiveness of evaluations.

Monitoring regulatory changes is imperative, especially in staying updated on amendments to 21 CFR Part 210 and other pertinent regulations. This proactive strategy ensures that regulatory measures, such as 21 CFR Part 210, remain relevant and effective, allowing for prompt modifications to SOPs and practices as necessary.

- Engage in Continuous Improvement: Cultivating a culture of continuous improvement is essential. This involves routinely reviewing processes and soliciting feedback from staff. Such an iterative approach not only enhances adherence but also fosters an environment where employees feel empowered to contribute to operational excellence.

By diligently following these steps, R&D managers can effectively implement adherence strategies that significantly elevate product standards and safety, ultimately reinforcing the organization's commitment to regulatory standards and operational integrity.

Utilize Resources and Tools: Enhancing Compliance Efforts with Practical Solutions

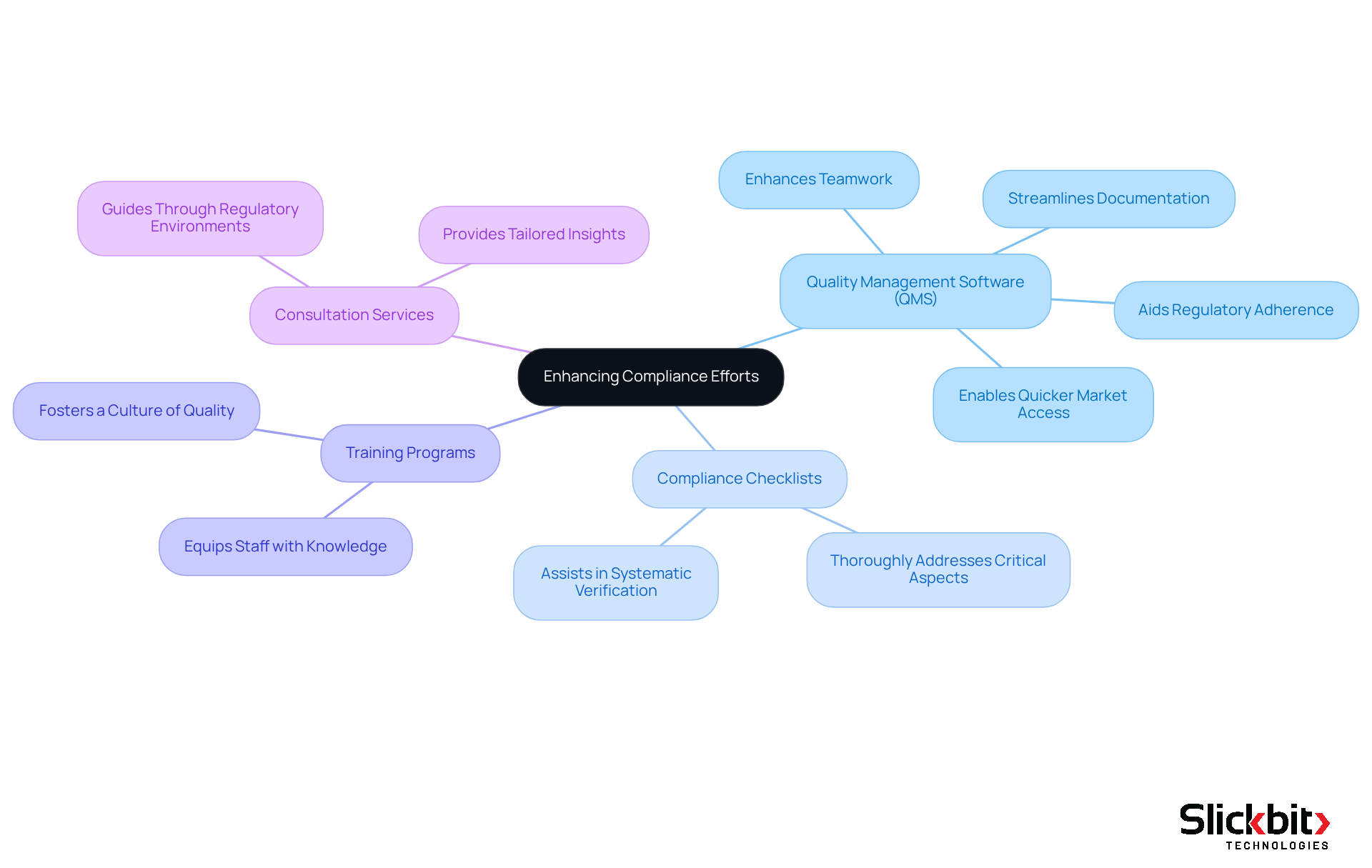

To bolster compliance initiatives, R&D managers can leverage a variety of resources and tools.

-

Quality Management Software (QMS): Implementing an electronic quality management system (eQMS) significantly streamlines documentation, training, and audit processes. A contemporary QMS enhances teamwork among departments and aids adherence to regulatory standards, ultimately enabling quicker market access.

-

Utilizing compliance checklists specifically designed for 21 CFR Part 210 ensures that all critical aspects are thoroughly addressed during audits and inspections. These checklists have proven effective in maintaining conformity, assisting organizations in systematically verifying adherence to regulations.

-

Training Programs: Investing in comprehensive training initiatives centered on current Good Manufacturing Practices (cGMP) equips staff at all levels with essential knowledge to maintain regulatory standards. Continuous education fosters a culture of quality and accountability within the organization.

-

Consultation Services: Engaging with regulatory consultants who specialize in 21 CFR Part 210 provides tailored insights and guidance. These specialists can assist organizations in navigating intricate regulatory environments, guaranteeing that adherence strategies are both effective and aligned with industry best practices.

By effectively utilizing these resources and tools, R&D managers can significantly enhance their compliance efforts, ensuring strict adherence to regulatory standards and safeguarding product quality.

Conclusion

Understanding and implementing 21 CFR Part 210 is essential for R&D managers who aim to ensure the safety, quality, and efficacy of pharmaceutical products. This regulation delineates the minimum current good manufacturing practices (cGMP) required for drug production, establishing a framework that not only guides compliance but also enhances operational excellence. By mastering these guidelines, organizations can safeguard public health and maintain a competitive advantage in the pharmaceutical sector.

The article highlights several critical focus areas for R&D managers, including:

- The development of a robust Quality Management System (QMS)

- Meticulous documentation practices

- Comprehensive personnel training

Regular internal audits and the implementation of effective compliance strategies—such as the creation of Standard Operating Procedures (SOPs) and ongoing risk evaluations—are also paramount. Furthermore, leveraging advanced resources like electronic quality management systems and compliance checklists can streamline adherence efforts, facilitating the achievement of regulatory standards.

Ultimately, the significance of 21 CFR Part 210 transcends mere compliance; it embodies a commitment to quality and safety that benefits both organizations and consumers alike. R&D managers are urged to embrace these regulations not solely as a legal obligation but as an opportunity to cultivate a culture of continuous improvement. By prioritizing compliance and utilizing available resources, organizations can elevate their product standards, ensuring they not only meet but exceed industry expectations.

Frequently Asked Questions

What is 21 CFR Part 210?

21 CFR Part 210 outlines the minimum current good manufacturing practices (cGMP) essential for drug production, processing, packing, or holding.

What are the key definitions in 21 CFR Part 210?

The key definitions include: - Batch: A specific quantity of drug exhibiting uniform characteristics. - Component: Any ingredient utilized in the drug product. - Drug Product: The finished dosage form.

Why is understanding these definitions important?

Understanding these definitions is crucial as they establish the groundwork for compliance and assurance in pharmaceutical manufacturing.

How can AI technologies assist with compliance to 21 CFR Part 210?

AI technologies can detect patterns in FDA inspections, providing critical insights into systemic risks and recurring violations, which can enhance adherence efforts.

What is the ultimate goal of adhering to 21 CFR Part 210 regulations?

Strict adherence to these regulations ensures that drug products are safe, effective, and of high quality, ultimately safeguarding public health.