Overview

The article delineates four essential steps for R&D managers to master compliance with 21 CFR 211 regulations. These steps encompass:

- Understanding the regulations

- Establishing robust documentation practices

- Implementing effective root cause analysis techniques

- Adopting continuous compliance monitoring strategies

Each step is bolstered by practical actions and the integration of AI tools, which enhance compliance efforts. This ensures that organizations uphold adherence to current good manufacturing practices within the pharmaceutical industry.

Introduction

Navigating the labyrinth of regulatory compliance presents a formidable challenge for R&D managers, particularly regarding the stringent requirements of 21 CFR 211. This regulation governs current good manufacturing practices within the pharmaceutical industry and is vital for ensuring product quality and safety. Mastering the essential steps outlined in this guide enables R&D leaders to streamline compliance processes and enhance operational efficiency. However, a critical question arises: how can organizations effectively integrate these compliance measures while adapting to the ever-evolving landscape of regulations and industry standards?

Understand 21 CFR 211 Regulations

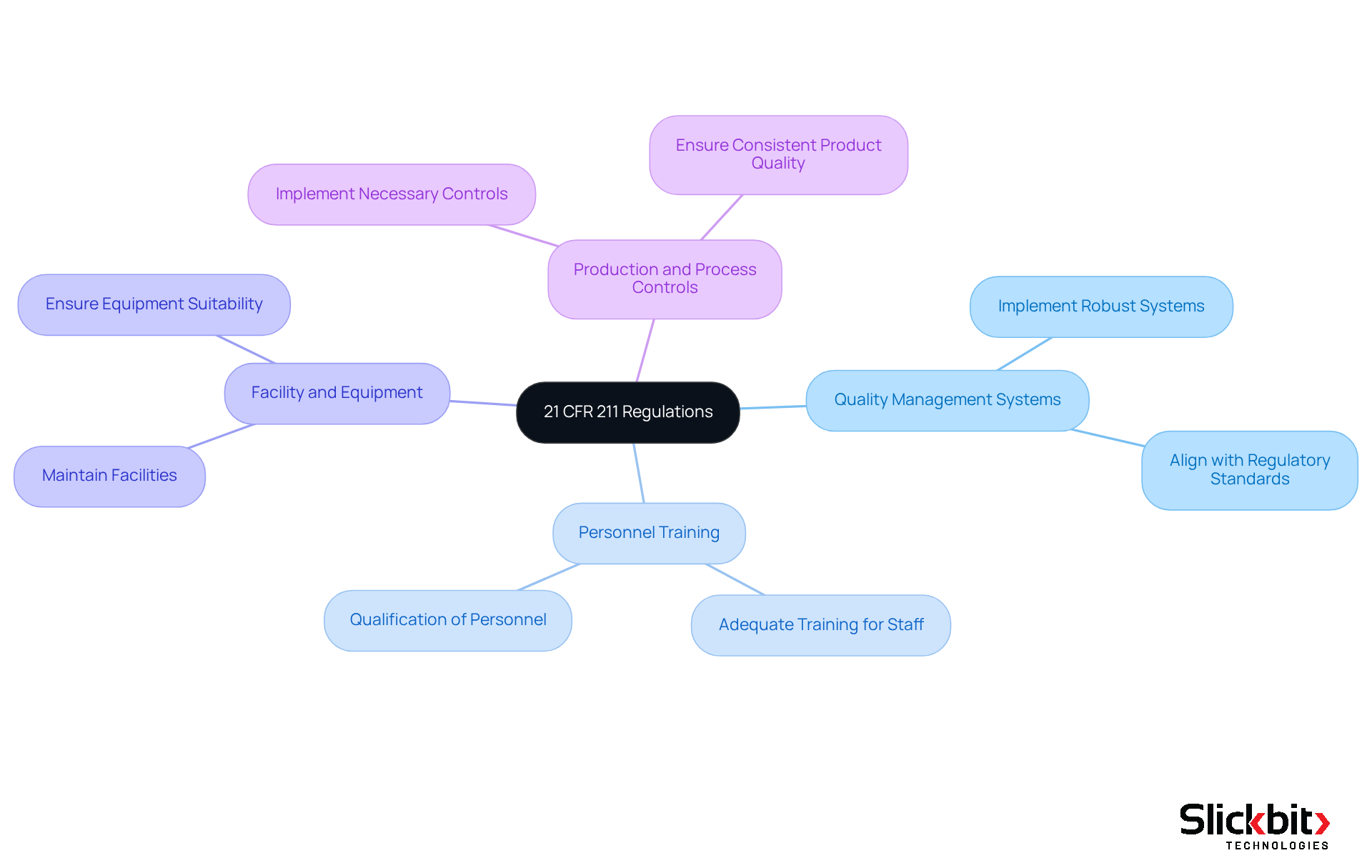

To master compliance with 21 CFR 211, R&D managers must first familiarize themselves with the regulations that govern current good manufacturing practices (cGMP) for pharmaceuticals. This foundational understanding encompasses the specific requirements for production, quality control, and record-keeping. Key areas that warrant attention include:

- Quality Management Systems: It is imperative that your organization implements a robust quality management system that aligns with the standards outlined in the regulations.

- Personnel Training: All staff involved in the manufacturing process must be adequately trained and qualified to ensure compliance and operational excellence.

- Facility and Equipment: A thorough comprehension of the requirements for maintaining facilities and equipment is essential to guarantee their suitability for intended use.

- Production and Process Controls: Familiarity with the necessary controls is crucial to ensuring consistent product quality.

By grasping these essential elements, R&D managers can navigate the intricacies of regulations more effectively and prepare for the successful execution of subsequent steps.

Establish Robust Documentation Practices

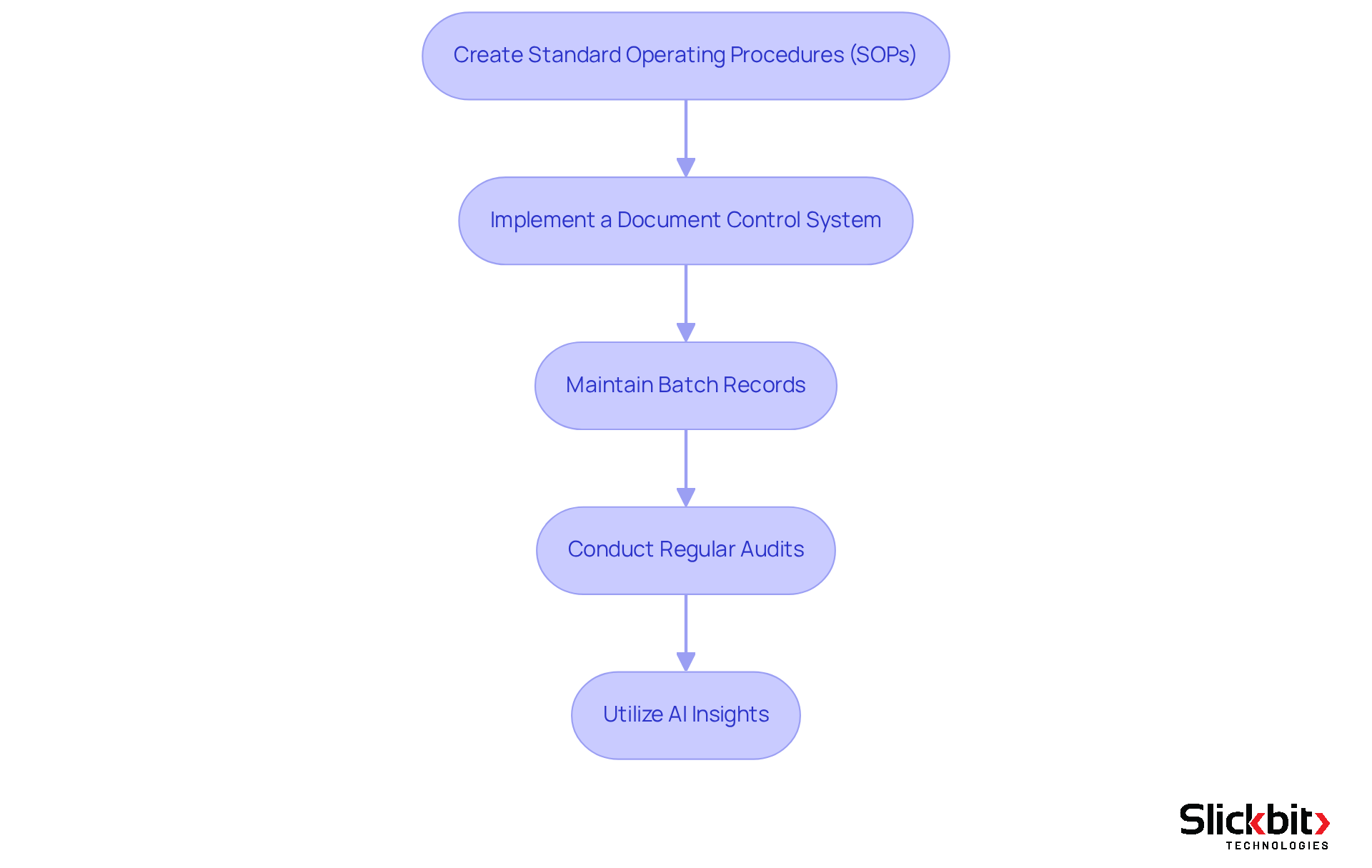

Establishing robust documentation practices is essential for demonstrating adherence to 21 CFR 211. To effectively implement these practices, consider the following actionable steps, enhanced by insights from AI technology:

-

Create Standard Operating Procedures (SOPs): Develop clear SOPs for all processes related to manufacturing and quality control. These documents should be easily accessible and regularly updated. Furthermore, leveraging AI tools can help analyze compliance trends and identify areas where SOPs may require revision.

-

Implement a Document Control System: Utilize a document management system to track revisions, approvals, and distribution of all critical documents. In addition, AI can automate this task, ensuring that the most current documents are always in use and easily retrievable.

-

Maintain Batch Records: It is crucial to ensure that batch production records are complete and accurate, detailing every step of the manufacturing process. AI can assist in monitoring these records for discrepancies and ensuring adherence to regulatory standards.

-

Conduct Regular Audits: Schedule periodic reviews of documentation practices to identify areas for improvement and ensure compliance with regulatory standards. Consequently, AI can simplify this process by examining previous audit results and highlighting potential regulatory risks.

By emphasizing documentation and utilizing AI insights, R&D leaders can establish a strong foundation for compliance, enabling more efficient audits and inspections.

Implement Effective Root Cause Analysis Techniques

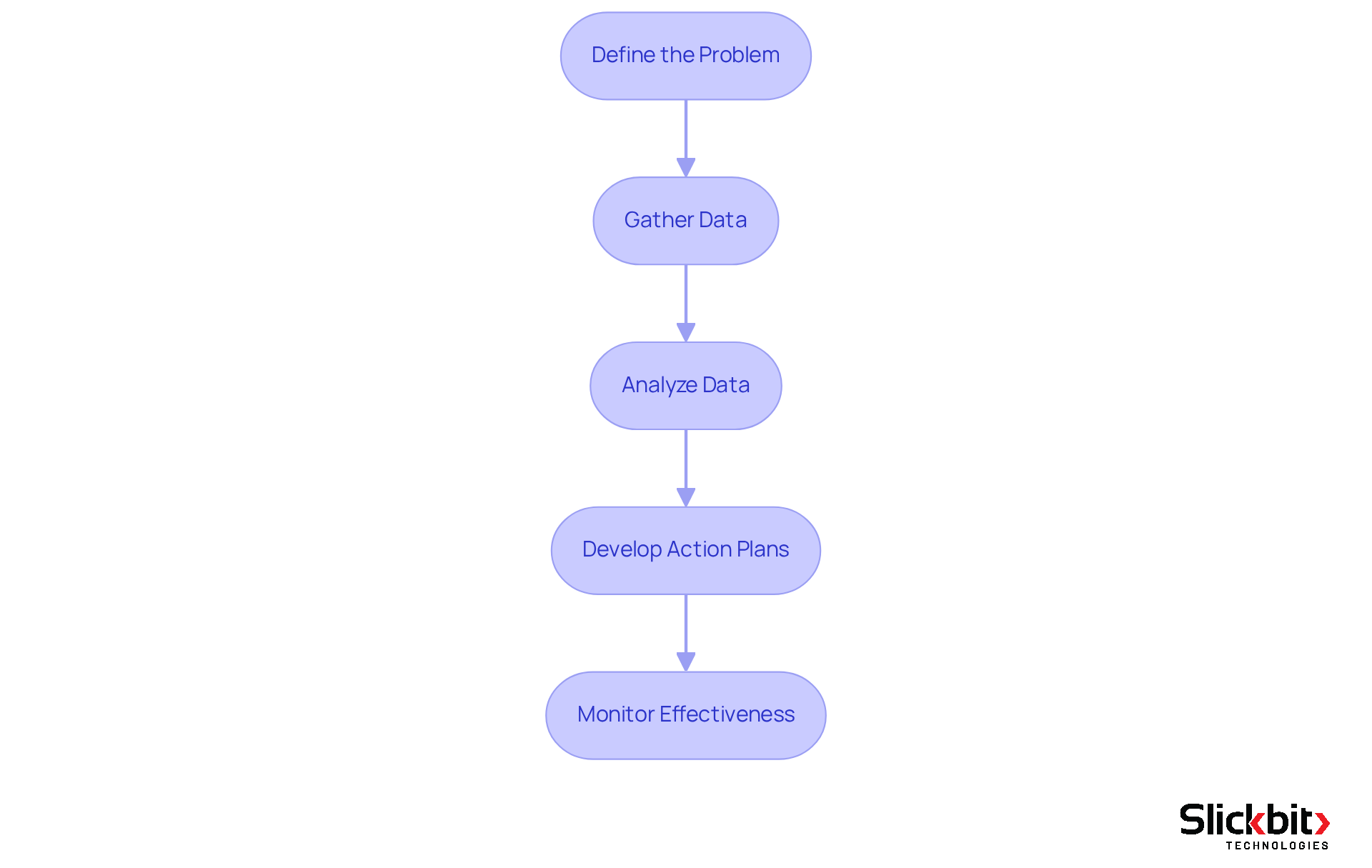

To effectively tackle regulatory issues, R&D managers must implement root cause analysis (RCA) techniques, leveraging advanced AI solutions such as Slickbit.ai's Vault Redact and Trend 483. Start by defining the problem: clearly articulate the compliance issue at hand, including its impact on operations. This initial step sets the stage for a comprehensive approach to resolution.

Next, gather data. Collect relevant documentation related to the issue, including production records and employee feedback. Utilizing Vault Redact streamlines this process by automating the identification and removal of PII and PHI from documents, ensuring that sensitive information is handled securely. This meticulous data collection is crucial for informed analysis.

Once the data is gathered, analyze it. Employ techniques like the 5 Whys or Fishbone Diagram to identify the underlying causes of the problem. Trend 483 can assist in this analysis by pinpointing patterns in systemic risks and recurring violations from FDA 483s, providing deeper insights into regulatory issues. This analytical phase is vital for uncovering root causes that may otherwise remain hidden.

Following the analysis, develop action plans. Create targeted strategies to address the identified root causes, ensuring that these plans are specific, measurable, and time-bound. This structured approach fosters accountability and clarity in implementation.

Finally, monitor effectiveness. After implementing corrective actions, it is essential to track their effectiveness to prevent recurrence of the issue. Insights gained from Trend 483 can aid in monitoring adherence over time and refining action plans as necessary. By utilizing these methods and incorporating Slickbit.ai's AI-driven solutions, R&D leaders can cultivate a culture of ongoing enhancement, significantly improving regulatory efforts.

Adopt Continuous Compliance Monitoring Strategies

To ensure ongoing compliance with the regulations outlined in 21 CFR 211, R&D leaders must implement continuous monitoring strategies. This proactive approach not only enhances operational efficiency but also fortifies the organization's commitment to regulatory adherence. Here are key steps to implement:

-

Utilize Technology: Leverage AI-driven tools like Slickbit's Trend 483 to automate compliance monitoring and data analysis. This tool not only detects trends in systemic risks and recurring violations from FDA 483s but also enables R&D managers to search, filter, and examine complete 483s for deeper insights, which is essential for effective oversight in life sciences.

-

Establish Key Performance Indicators (KPIs): Define KPIs related to adherence, such as the rate of adherence deviations and the time taken to resolve them. Statistics indicate that organizations that frequently assess KPIs experience a notable enhancement in performance adherence.

-

Conduct Regular Training: Provide ongoing training for staff to keep them informed about regulations and best practices. This ensures that the team is well-prepared to effectively address regulatory challenges, as evidenced by successful training initiatives in various projects.

-

Engage in Internal Audits: Schedule regular internal audits to evaluate adherence and identify areas for improvement. These audits serve as a proactive measure to detect potential regulatory issues before they escalate, similar to the internal procedures adopted by leading organizations in the field.

-

Stay Informed: Remain updated on changes in regulations and industry standards to ensure that your adherence strategies remain relevant. Engaging with industry leaders and leveraging their insights can provide significant guidance on navigating evolving regulatory landscapes.

By implementing these strategies, R&D managers can foster a proactive compliance culture that minimizes risks and enhances operational efficiency, ultimately reinforcing the organization's dedication to regulatory adherence.

Conclusion

Mastering compliance with 21 CFR 211 is essential for R&D managers, as it establishes the foundation for ensuring that pharmaceutical products adhere to the requisite quality and safety standards. A comprehensive understanding of these regulations, paired with effective practices, enables organizations to navigate the complexities of compliance and achieve operational excellence.

This article delineates four critical steps:

- Understanding the regulations

- Establishing robust documentation practices

- Implementing effective root cause analysis techniques

- Adopting continuous compliance monitoring strategies

Each of these elements is integral to constructing a thorough compliance framework that not only satisfies regulatory obligations but also enhances overall organizational performance. Furthermore, leveraging technology, such as AI-driven tools, can further streamline these processes, facilitating adherence and boosting efficiency.

Ultimately, the commitment to 21 CFR 211 compliance extends beyond merely avoiding regulatory pitfalls; it encompasses fostering a culture of quality and continuous improvement within the organization. By prioritizing compliance and actively engaging in best practices, R&D managers can significantly bolster the integrity of the pharmaceutical industry and ensure that their products are safe and effective for consumers. Embracing these strategies is imperative for any organization aiming to excel in the dynamic landscape of pharmaceutical development.

Frequently Asked Questions

What is 21 CFR 211?

21 CFR 211 refers to the regulations that govern current good manufacturing practices (cGMP) for pharmaceuticals, outlining the requirements for production, quality control, and record-keeping.

Why is it important for R&D managers to understand 21 CFR 211?

R&D managers must understand 21 CFR 211 to ensure compliance with the regulations, which is essential for operational excellence in pharmaceutical manufacturing.

What are the key areas of focus for compliance with 21 CFR 211?

The key areas include Quality Management Systems, Personnel Training, Facility and Equipment maintenance, and Production and Process Controls.

What is a Quality Management System in the context of 21 CFR 211?

A Quality Management System is a structured system that organizations implement to ensure compliance with the standards outlined in 21 CFR 211.

What is the significance of Personnel Training under 21 CFR 211?

Personnel Training ensures that all staff involved in the manufacturing process are adequately trained and qualified, which is crucial for compliance and operational excellence.

How does 21 CFR 211 address Facility and Equipment requirements?

21 CFR 211 requires a thorough understanding of the requirements for maintaining facilities and equipment to ensure they are suitable for their intended use.

Why are Production and Process Controls important in 21 CFR 211?

Production and Process Controls are important to ensure consistent product quality, which is a key aspect of compliance with the regulations.