Overview

The article presents ten essential strategies to enhance Overall Equipment Effectiveness (OEE) in pharmaceutical manufacturing. It underscores the critical role of:

- Integrating AI solutions

- Establishing benchmarks

- Analyzing OEE components

- Fostering a culture of continuous improvement

Evidence supports these strategies, demonstrating how AI-driven analytics can optimize production processes, streamline operations, and ensure compliance. Ultimately, these approaches lead to improved efficiency and reduced downtime in the industry, paving the way for a more productive future.

Introduction

In the fast-paced world of pharmaceutical manufacturing, the pursuit of operational excellence has never been more critical. Overall Equipment Effectiveness (OEE) stands as a vital metric, steering organizations toward heightened efficiency and compliance. This article explores ten actionable tips designed to significantly enhance OEE within the pharma sector, ranging from the utilization of AI solutions to the implementation of preventive maintenance strategies. Yet, a pressing challenge persists: how can organizations effectively integrate these practices to address existing inefficiencies and foster continuous improvement?

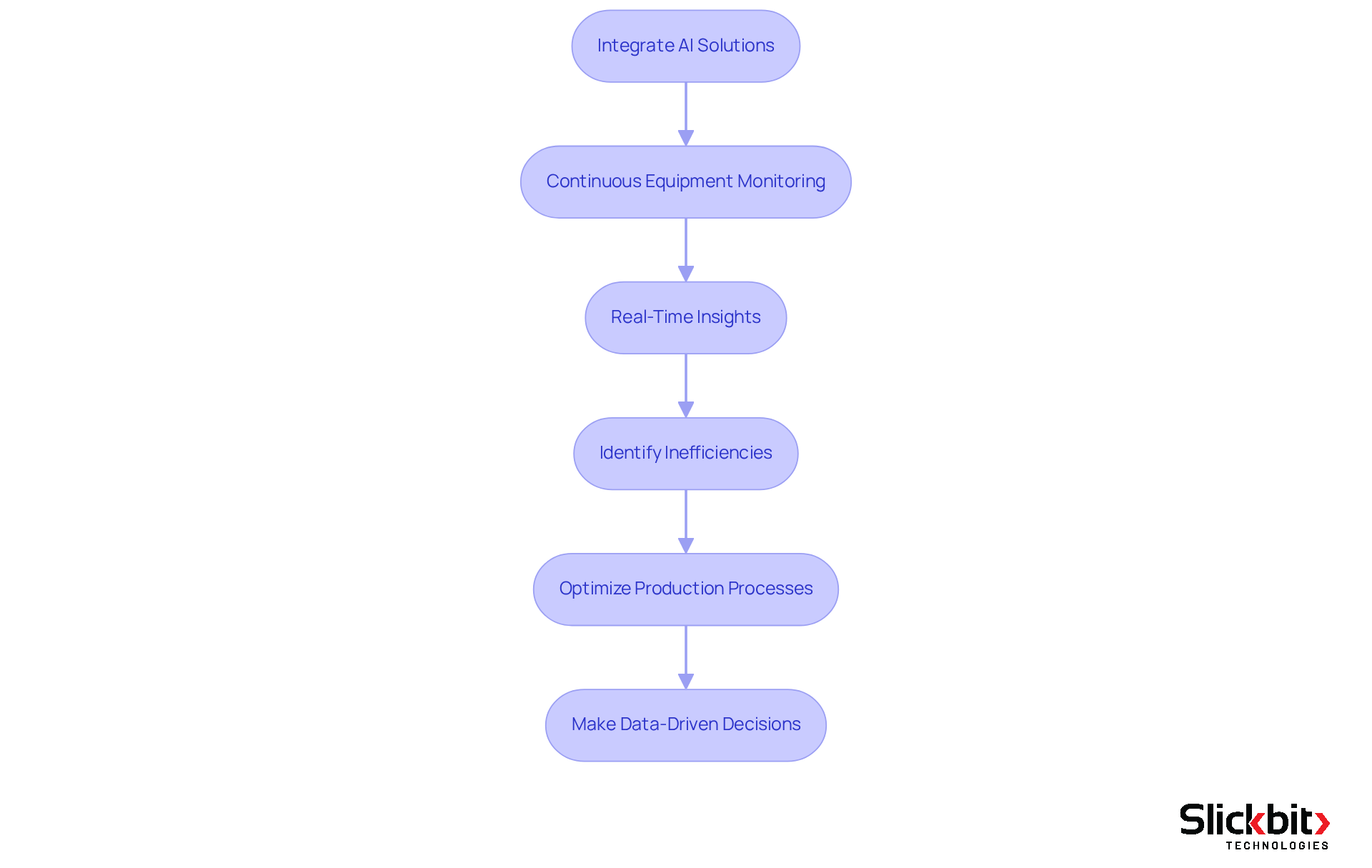

Slickbit: Leverage AI Solutions for Enhanced OEE in Pharma Manufacturing

Slickbit.ai delivers cutting-edge AI solutions specifically designed to enhance OEE (Overall Equipment Effectiveness) within pharmaceutical manufacturing. By integrating AI-driven analytics and automation into existing workflows, organizations can significantly elevate efficiency, reduce downtime, and ensure compliance with regulatory standards.

For instance, AI agents continuously monitor equipment functionality, offering real-time insights that pinpoint inefficiencies and facilitate the optimization of production processes. This proactive strategy not only improves operational efficiency but also boosts OEE by empowering teams to make informed, data-driven decisions that align with industry best practices.

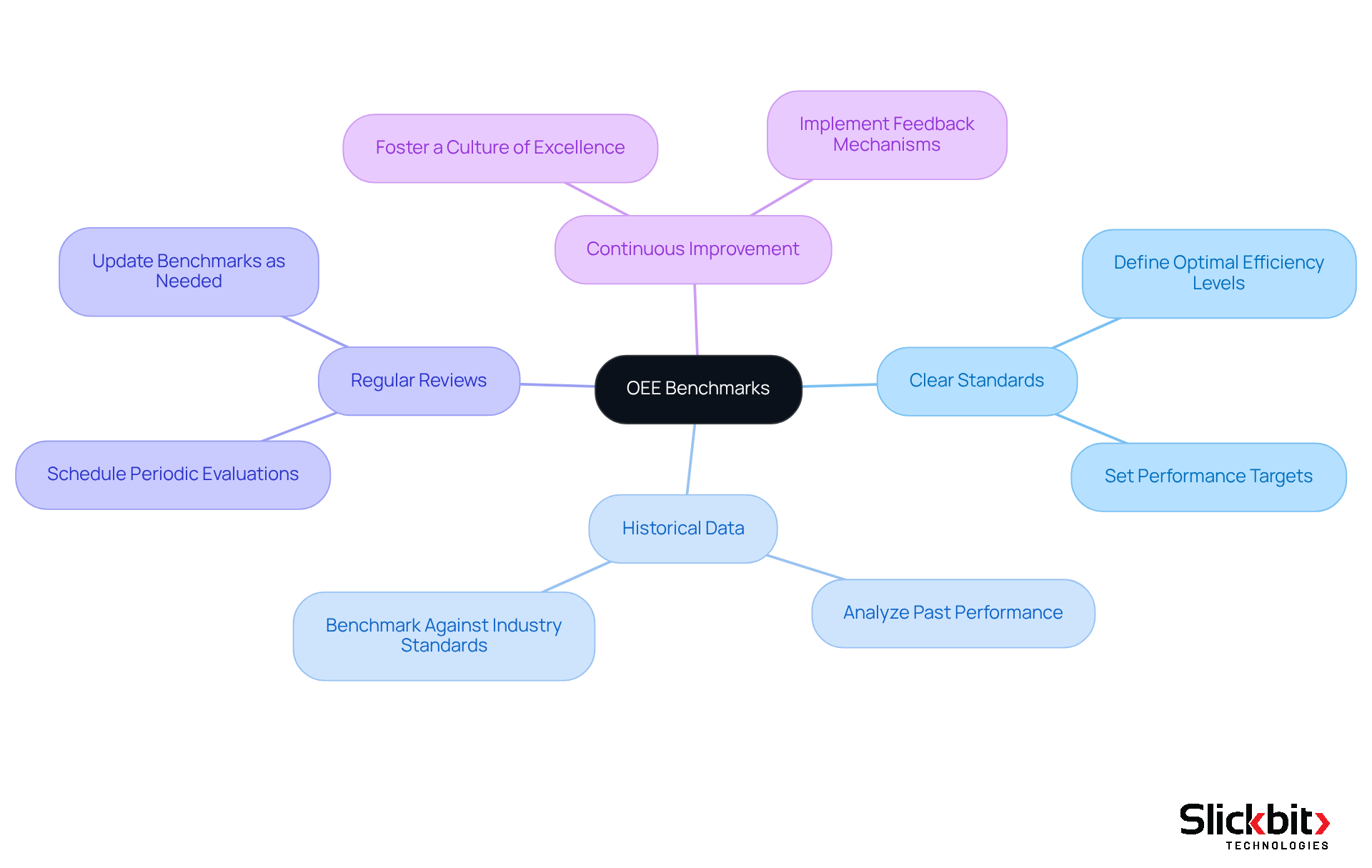

Establish OEE Benchmarks: Set Clear Performance Standards

To enhance OEE (Overall Equipment Effectiveness), it is crucial to establish clear standards that define optimal efficiency levels for both equipment and processes. These benchmarks should be grounded in historical data and industry standards, allowing teams to evaluate current performance against these established targets. Furthermore, regular reviews and updates of these benchmarks are essential to ensure they remain relevant and challenging. This practice not only drives continuous improvement but also fosters a culture of excellence within the organization.

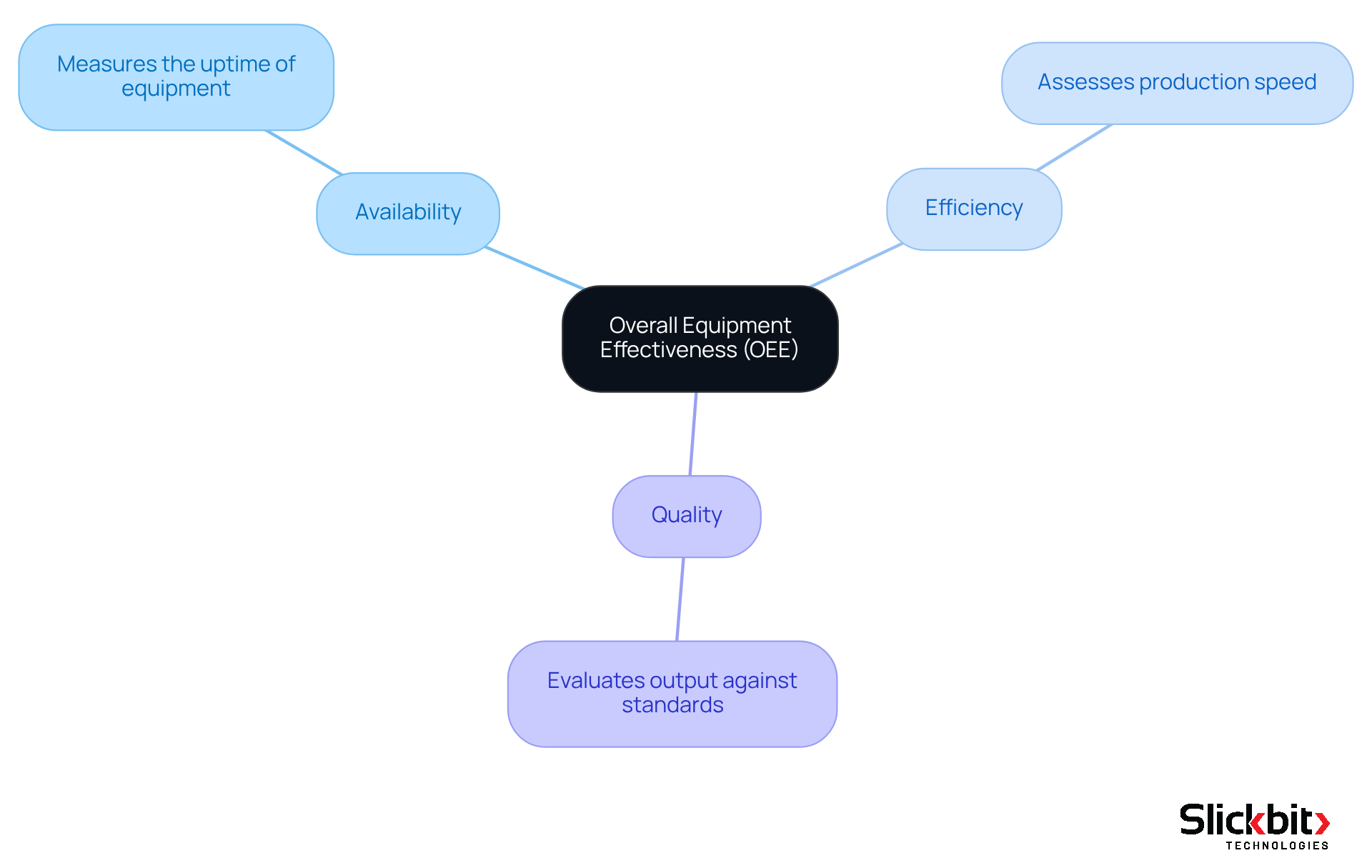

Analyze OEE Components: Focus on Availability, Performance, and Quality

OEE comprises three critical components: availability, efficiency, and quality. Understanding these elements is vital for identifying areas of loss within production processes.

- Availability measures the uptime of equipment.

- Efficiency assesses production speed.

- Quality evaluates how well the output meets established standards.

By focusing on these key areas, organizations can develop targeted strategies that significantly enhance overall effectiveness. Consequently, a comprehensive analysis of OEE (overall equipment effectiveness) not only highlights inefficiencies but also paves the way for informed decision-making and continuous improvement.

Calculate OEE Regularly: Monitor Progress and Trends

Calculating OEE (Overall Equipment Effectiveness) regularly is crucial for tracking progress and identifying trends within the pharmaceutical industry. This routine not only allows organizations to swiftly pinpoint deviations from expected results but also facilitates timely corrective actions.

Furthermore, employing AI tools, such as Slickbit's Trend 483, automates this process, providing valuable insights into adherence and operational efficiency. In addition, Slickbit's AI Inventory Assistant simplifies data collection and analysis, significantly reducing manual effort while enhancing accuracy in performance tracking.

These AI solutions not only streamline efficient OEE calculations but also support organizations in maintaining regulatory compliance by automating the identification of trends related to systemic risks and recurring violations.

![]()

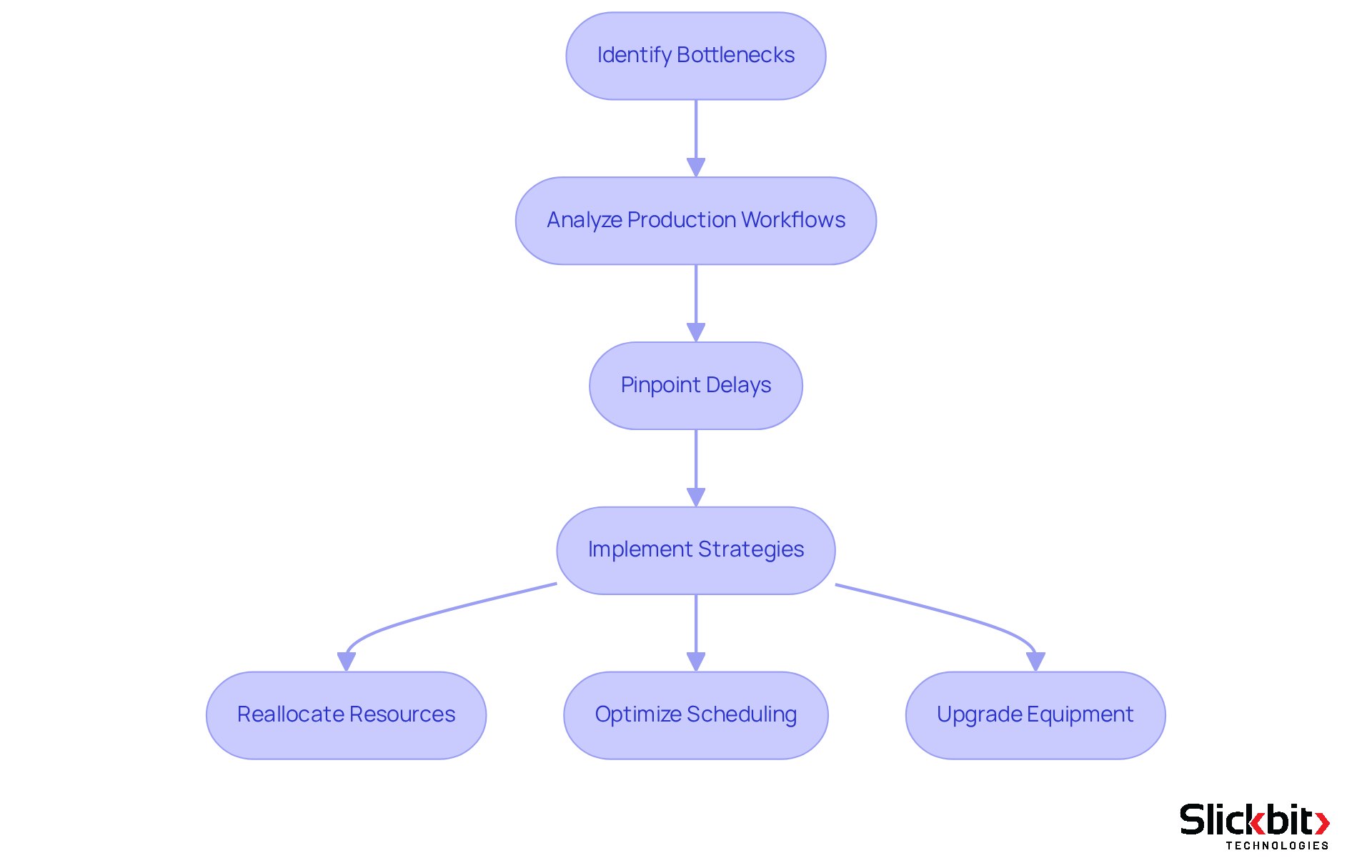

Identify Bottlenecks: Streamline Production Processes

Bottlenecks in production significantly hinder overall equipment effectiveness (OEE). Identifying these constraints necessitates a comprehensive analysis of production workflows. By leveraging AI analytics, organizations can accurately pinpoint where delays occur. Consequently, they can implement targeted strategies to alleviate these bottlenecks. This may involve:

- Reallocating resources

- Optimizing scheduling

- Upgrading equipment to enhance throughput

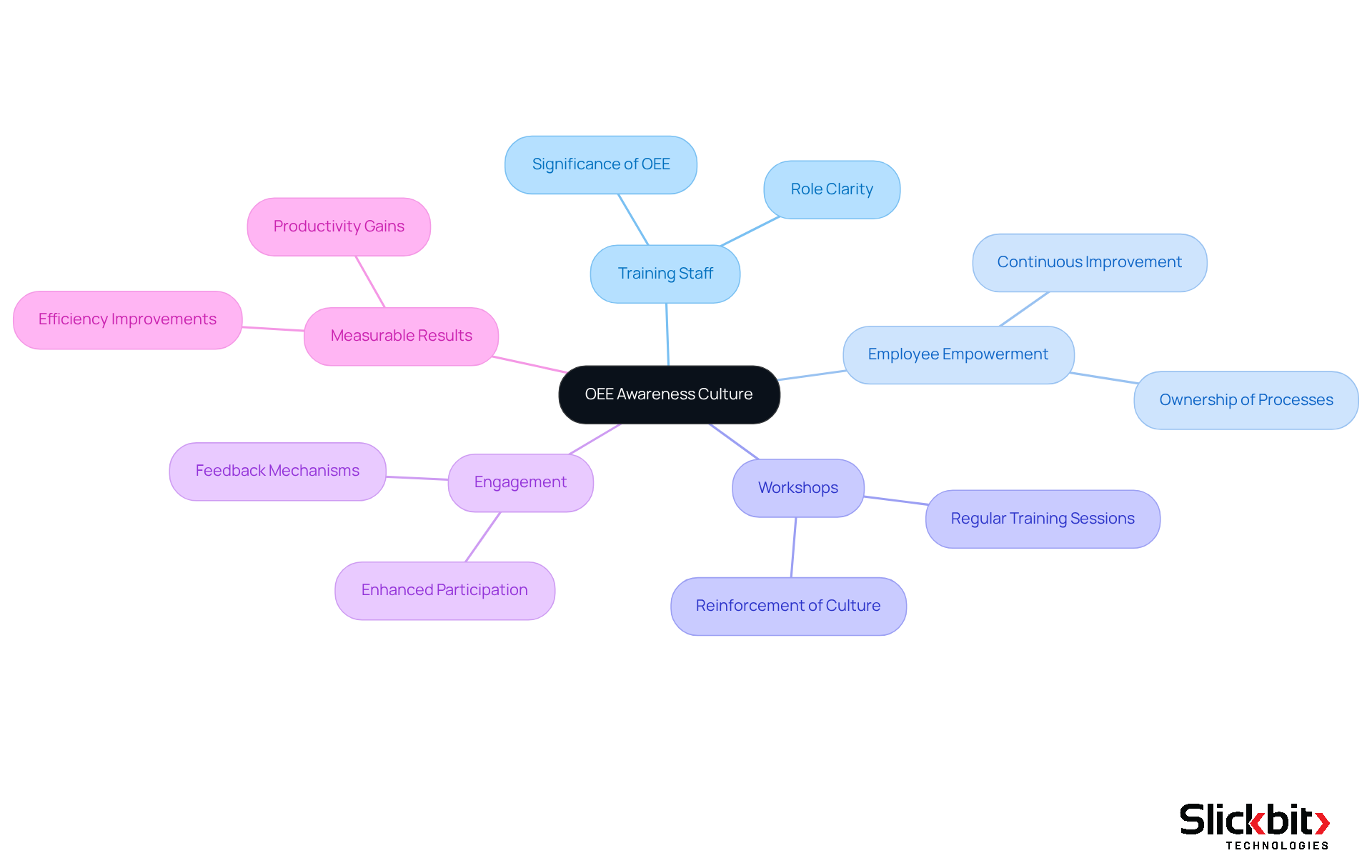

Train Staff: Foster a Culture of OEE Awareness

Training staff on the significance of OEE (Overall Equipment Effectiveness) and their specific roles in achieving it is paramount. By cultivating a culture of OEE awareness, companies can empower employees to take ownership of their processes, thereby contributing to ongoing improvement initiatives.

Furthermore, regular workshops and training sessions serve to reinforce this culture, ensuring that OEE remains a top operational priority. This proactive approach not only enhances employee engagement but also drives measurable results in efficiency and productivity.

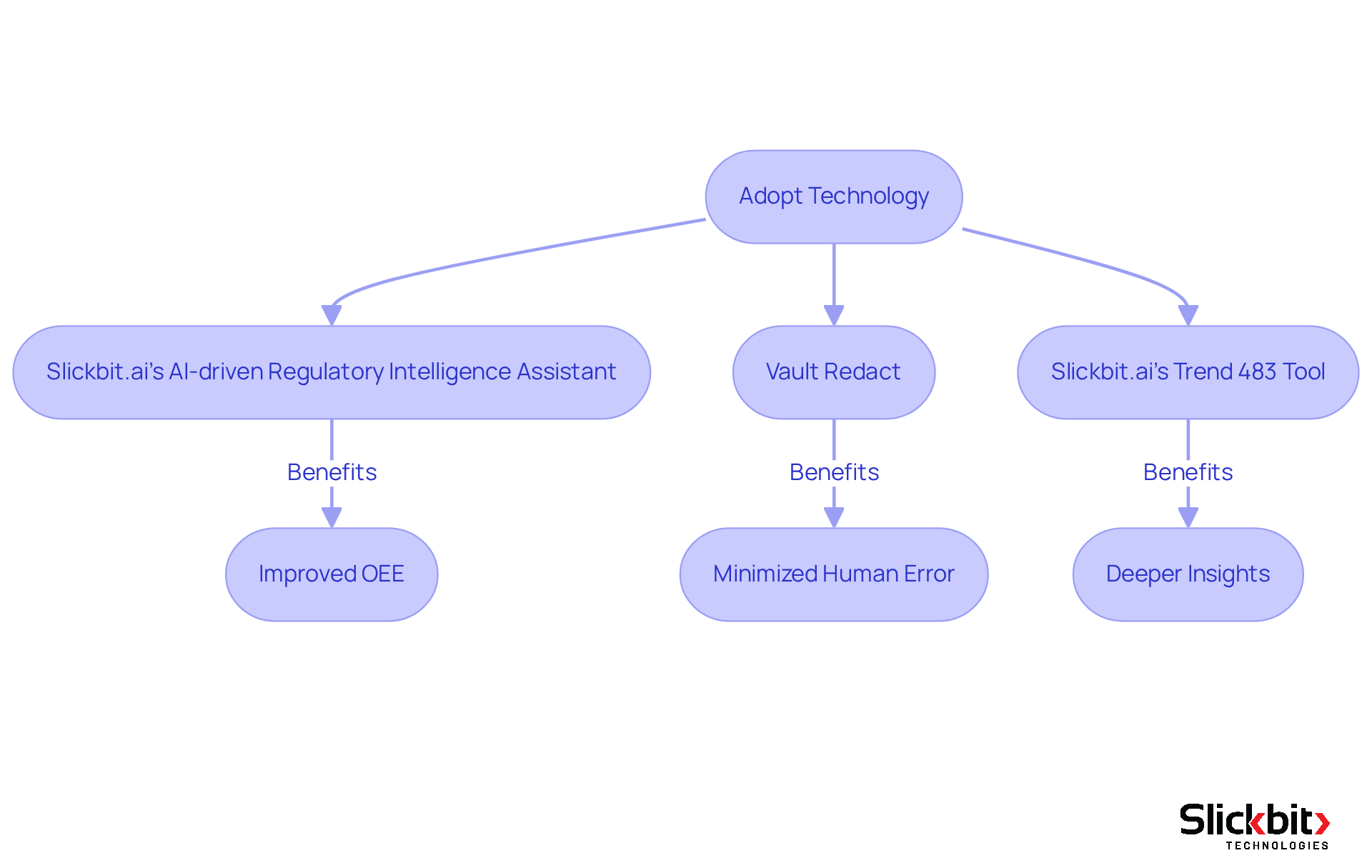

Adopt Technology: Use Automation to Boost Efficiency

The adoption of advanced technologies, such as automation and AI, significantly enhances efficiency in pharmaceutical manufacturing. Slickbit.ai's AI-driven Regulatory Intelligence assistant, Lumino, provides pharmaceutical teams with precise, traceable responses derived from FDA and international guidance documents. This capability guarantees adherence and informed decision-making, leading to improved oee overall equipment effectiveness.

In addition, Vault Redact automates the identification and removal of Personally Identifiable Information (PII) and Protected Health Information (PHI) from documents, thereby minimizing human error and enhancing data accuracy. By integrating these technologies into existing workflows, companies can achieve better oee overall equipment effectiveness while ensuring compliance with industry regulations.

Furthermore, Slickbit.ai's Trend 483 tool identifies trends in systemic risks and compliance issues, offering deeper insights that can streamline operations even further.

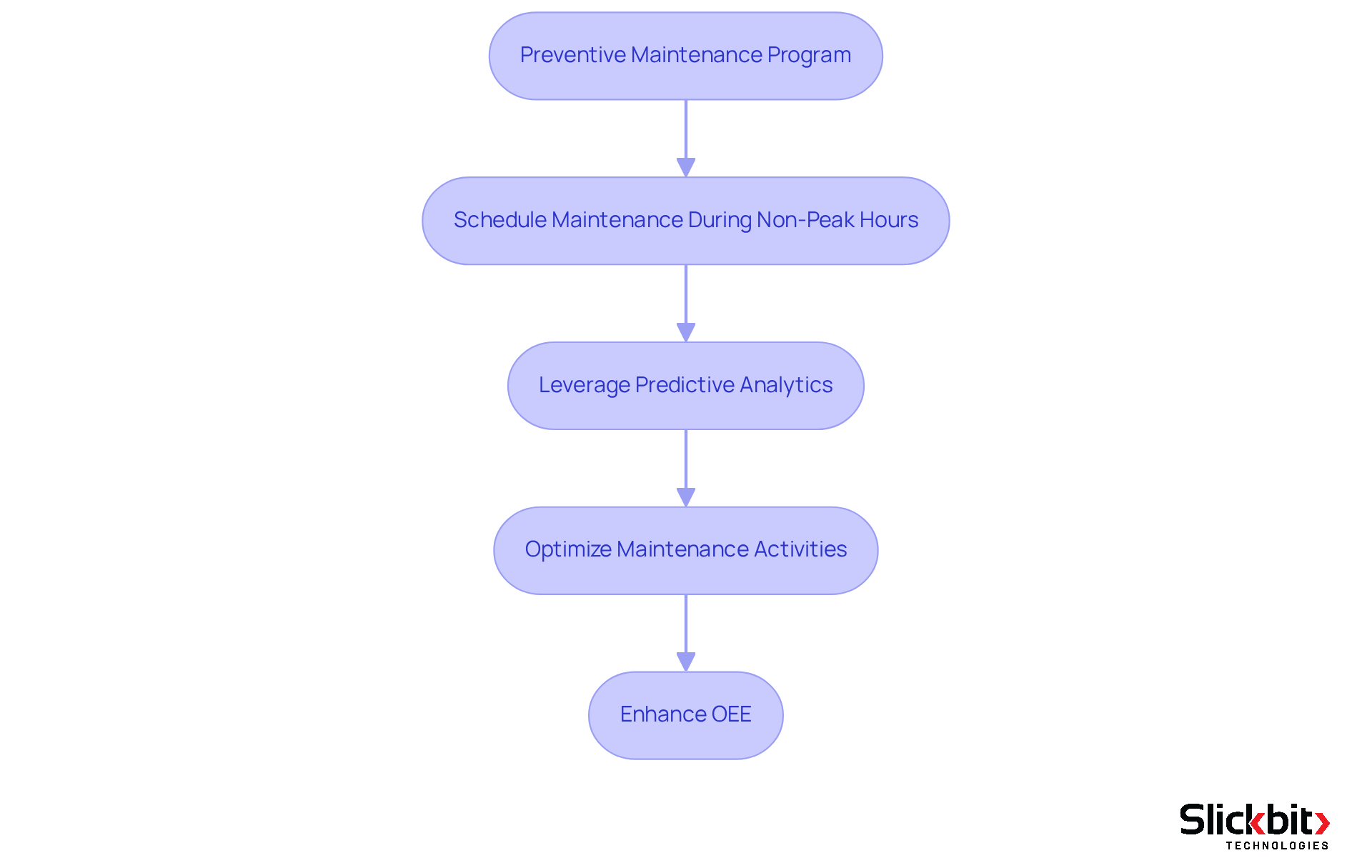

Implement Preventive Maintenance: Ensure Equipment Reliability

Implementing a robust preventive maintenance program is essential for ensuring equipment reliability. Unexpected breakdowns can significantly disrupt production, making regular maintenance checks and timely repairs imperative. By scheduling maintenance during non-peak hours and leveraging predictive analytics, companies can optimize their maintenance activities, thereby enhancing OEE (Overall Equipment Effectiveness). Furthermore, these strategies not only minimize downtime but also contribute to a more efficient operational environment. Consequently, organizations that prioritize preventive maintenance are better positioned to maintain productivity and achieve long-term success.

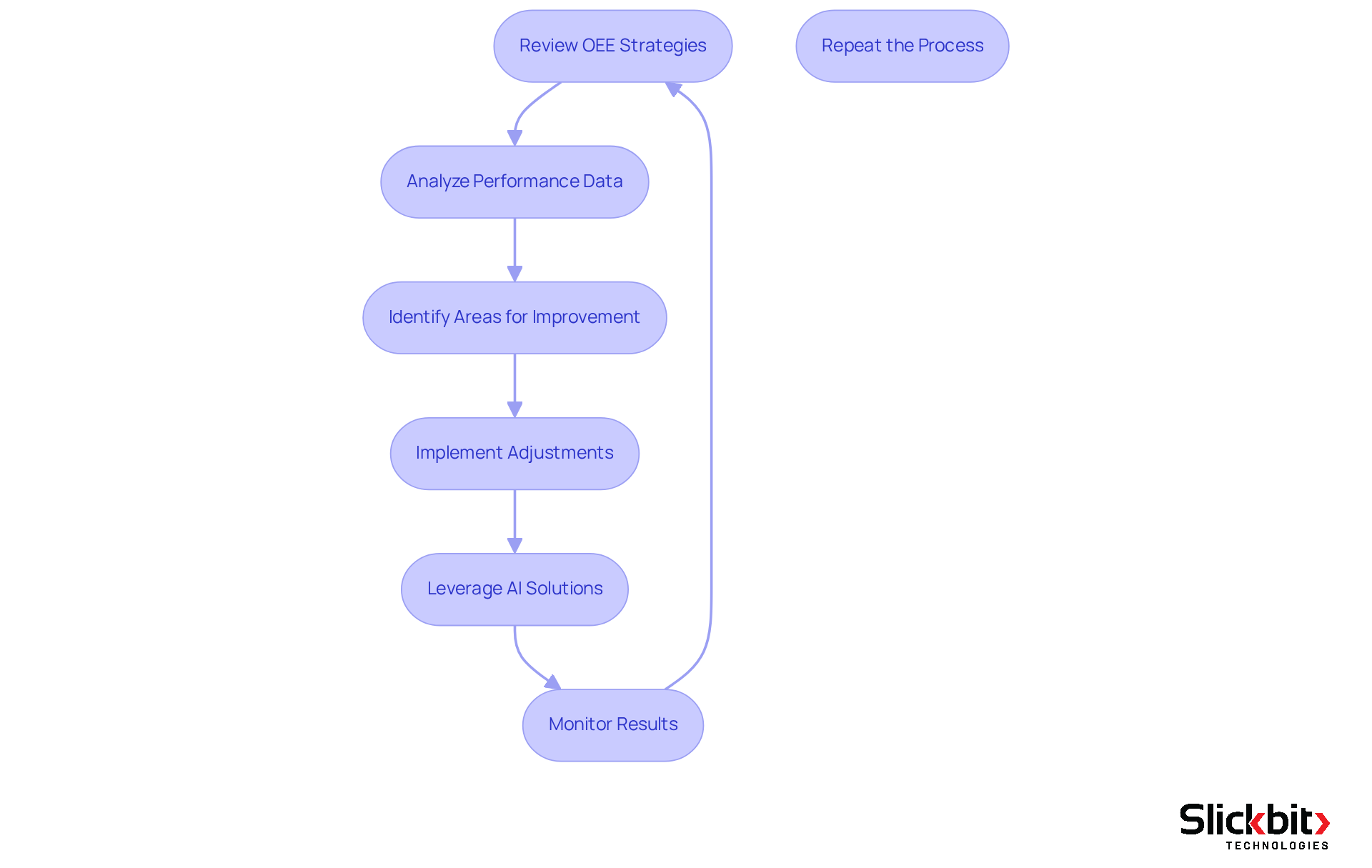

Embrace Continuous Improvement: Evolve OEE Strategies

Embracing a philosophy of continuous improvement is essential for enhancing OEE (Overall Equipment Effectiveness). Organizations must regularly review their OEE strategies and make necessary adjustments based on performance data and prevailing industry trends. By leveraging AI solutions, such as those offered by Slickbit, companies can streamline their operations and enhance compliance.

For instance, the AI Inventory Assistant empowers restaurants to manage inventory more effectively, thereby reducing waste and improving cost analysis. This iterative method not only enables the recognition of new opportunities for enhancement but also ensures that the organization remains agile in a swiftly evolving environment.

Ultimately, this transformation of business operations leads to improved overall efficiency.

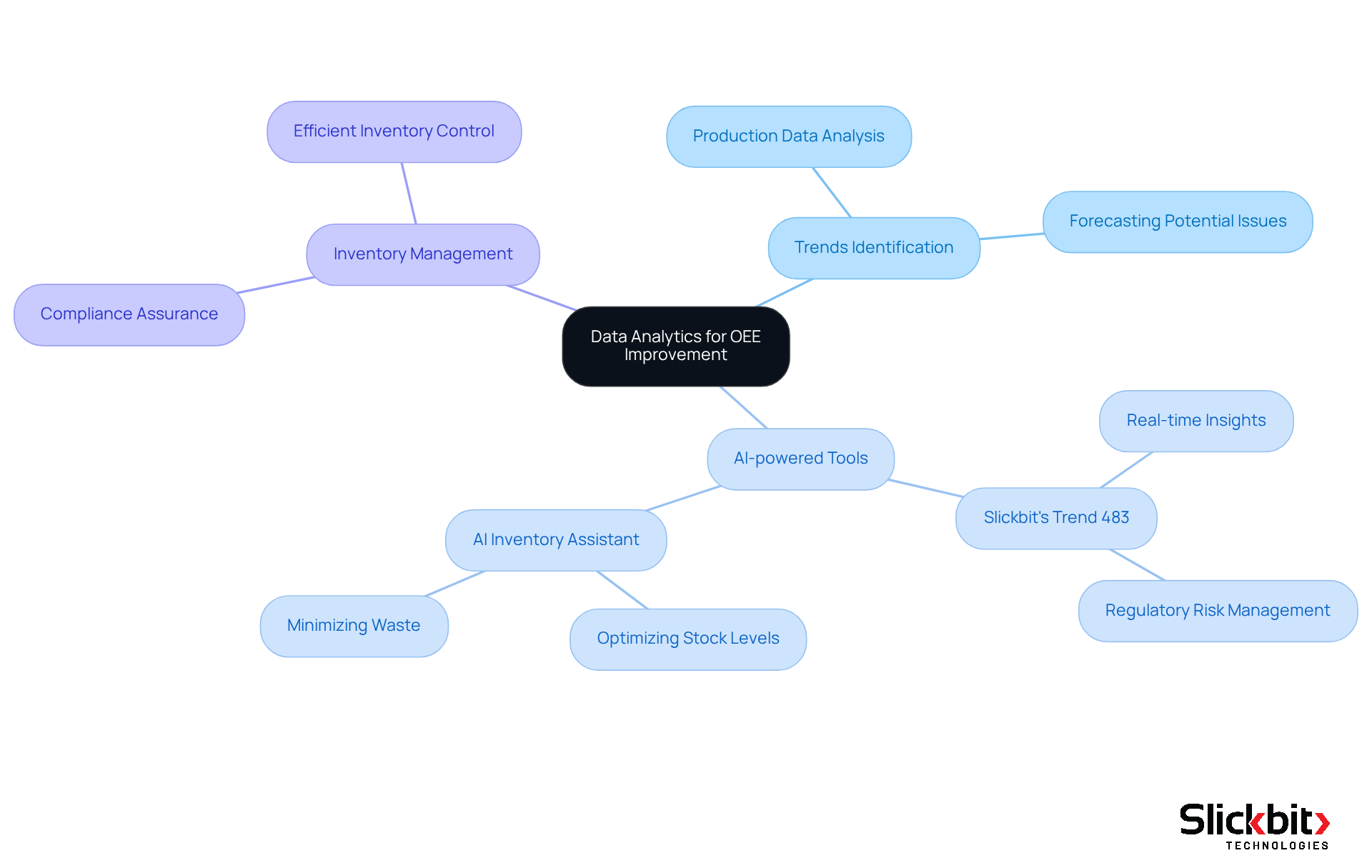

Utilize Data Analytics: Drive Informed Decisions for OEE Improvement

Utilizing data analytics is essential for driving informed decisions that enhance OEE (Overall Equipment Effectiveness) in the pharmaceutical industry. By thoroughly analyzing production data, companies can identify trends, forecast potential issues, and implement targeted solutions. AI-powered analytics tools, such as Slickbit's Trend 483, provide real-time insights into regulatory and operational risks. This capability allows teams to make proactive adjustments that significantly enhance OEE (Overall Equipment Effectiveness). Furthermore, the AI Inventory Assistant can be leveraged to manage pharmaceutical inventory efficiently, ensuring that stock levels are optimized while minimizing waste. Together, these tools empower organizations to enhance operational efficiency and ensure compliance in their processes.

Conclusion

Enhancing Overall Equipment Effectiveness (OEE) in pharmaceutical manufacturing is paramount for achieving operational excellence and ensuring compliance with industry standards. By integrating advanced technologies, establishing clear benchmarks, and cultivating a culture of continuous improvement, organizations can significantly elevate their efficiency and productivity.

This article outlines essential strategies for improving OEE, emphasizing the importance of:

- Setting performance benchmarks based on historical data

- Regularly calculating OEE to track progress

- Identifying production bottlenecks

- Implementing preventive maintenance

Furthermore, leveraging AI tools, such as those offered by Slickbit, facilitates real-time monitoring and data-driven decision-making, which are crucial for optimizing production processes.

Ultimately, the journey toward enhanced OEE in the pharmaceutical industry necessitates a commitment to innovation and a proactive approach to operational challenges. By embracing these strategies, organizations can not only improve their effectiveness but also ensure they remain competitive in a rapidly evolving market. Investing in OEE initiatives today will pave the way for a more efficient, compliant, and successful future in pharmaceutical manufacturing.

Frequently Asked Questions

What is Slickbit and how does it enhance OEE in pharmaceutical manufacturing?

Slickbit.ai provides AI solutions designed to improve Overall Equipment Effectiveness (OEE) in pharmaceutical manufacturing by integrating AI-driven analytics and automation into existing workflows, which helps elevate efficiency, reduce downtime, and ensure regulatory compliance.

How does AI contribute to monitoring equipment functionality?

AI agents continuously monitor equipment functionality, providing real-time insights that identify inefficiencies and facilitate the optimization of production processes, thereby improving operational efficiency and boosting OEE.

Why is it important to establish OEE benchmarks?

Establishing clear OEE benchmarks is crucial as it defines optimal efficiency levels for equipment and processes. These benchmarks should be based on historical data and industry standards, allowing teams to evaluate current performance and drive continuous improvement.

What are the components of OEE that organizations should analyze?

The three critical components of OEE are availability, efficiency, and quality. Availability measures equipment uptime, efficiency assesses production speed, and quality evaluates how well the output meets established standards.

How can organizations use the analysis of OEE components to improve performance?

By focusing on the components of OEE, organizations can identify areas of loss in production processes and develop targeted strategies to enhance overall effectiveness, leading to informed decision-making and continuous improvement.