Overview

This article presents ten strategies designed to enhance Overall Equipment Effectiveness (OEE) in manufacturing. It underscores the critical role of:

- Automation

- Predictive maintenance

- Real-time analytics

- Employee training

in achieving operational excellence. Each strategy is backed by compelling evidence that illustrates how these practices lead to significant reductions in downtime, increased productivity, and improved operational efficiency. Ultimately, these strategies contribute to the overall success of manufacturing operations.

Introduction

Manufacturers today are under mounting pressure to optimize their operations and maximize productivity. A pivotal method to achieve this is by enhancing Overall Equipment Effectiveness (OEE), a vital metric that encapsulates the efficiency of manufacturing processes. This article explores ten actionable strategies designed to significantly elevate OEE, encompassing the utilization of advanced AI solutions and the adoption of lean manufacturing principles.

However, a pressing challenge persists: how can organizations not only implement these strategies but also guarantee their seamless integration into existing workflows? Addressing these questions will illuminate the pathway to manufacturing success and operational excellence.

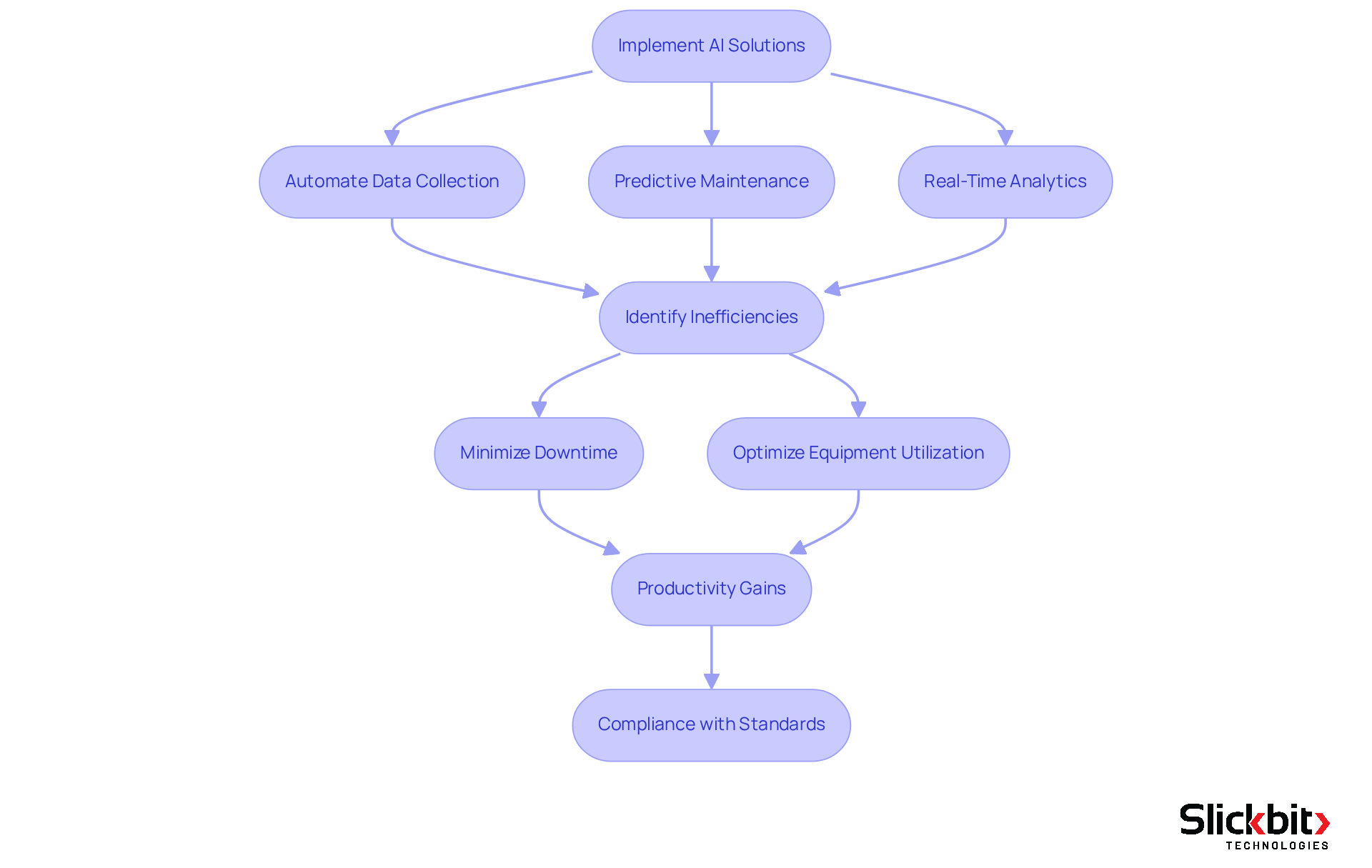

Slickbit: Leverage AI Solutions to Optimize OEE

Slickbit.ai delivers cutting-edge AI solutions designed to significantly enhance OEE for manufacturing through the automation of data collection, predictive maintenance, and real-time analytics. By embedding AI within manufacturing workflows, companies can swiftly identify inefficiencies, minimize downtime, and optimize equipment utilization. This approach not only leads to substantial productivity gains but also ensures compliance with stringent industry standards. For example, predictive maintenance strategies can reduce unplanned downtime by up to 45%, while AI-driven analytics facilitate continuous monitoring of equipment performance, enabling proactive interventions before issues escalate.

Furthermore, Slickbit's AI Integration Services support the seamless incorporation of AI into existing systems, thereby enhancing operational efficiency. Real-world applications, such as the Festo AX Motions Insights Pneumatic app, exemplify how AI can monitor pneumatic systems for anomalies, effectively preventing costly machine failures and boosting overall productivity. As manufacturers increasingly adopt AI technologies, they can anticipate not only improved OEE for manufacturing but also a competitive advantage in the rapidly evolving landscape of Life Sciences.

Additionally, Slickbit's AI Training & Workshops empower teams with the essential skills needed to leverage these technologies effectively, ensuring that organizations remain at the forefront of innovation in their respective fields.

Predictive Maintenance: Enhance Equipment Reliability and Uptime

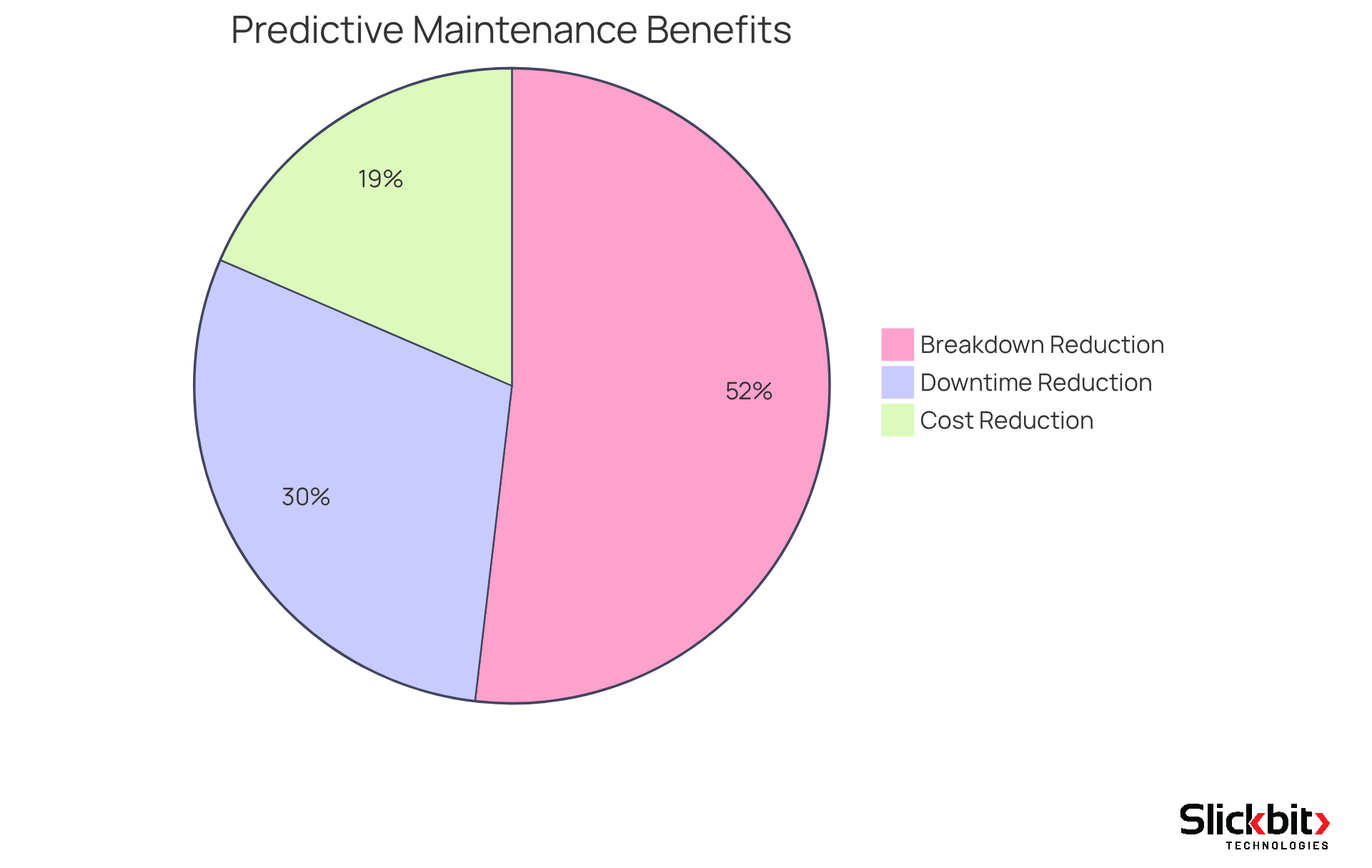

Predictive maintenance strategies harness the power of AI algorithms to scrutinize both historical and real-time data, facilitating precise predictions of equipment failures. This proactive methodology significantly boosts equipment reliability and maximizes uptime, thereby ensuring seamless production processes.

By implementing predictive analytics, organizations can achieve an average reduction in downtime ranging from 35% to 45%, translating into substantial cost savings and improved operational efficiency. Furthermore, predictive maintenance can result in a remarkable 70% decrease in equipment breakdowns and a reduction in maintenance costs by up to 25%.

For example, airlines that have adopted predictive analytics report a 35% decline in flight delays, attributed to timely maintenance interventions. Additionally, predictive maintenance minimizes emergency repairs and optimizes maintenance schedules, allowing repairs to occur during off-peak hours, thus preventing disruptions.

As Laura Cadden aptly states, predictive maintenance is a strategic game-changer that enables organizations to enhance their operations and remain competitive in an increasingly demanding landscape. Moreover, techniques such as hierarchical clustering play a vital role in identifying failure modes, further amplifying the efficacy of predictive maintenance.

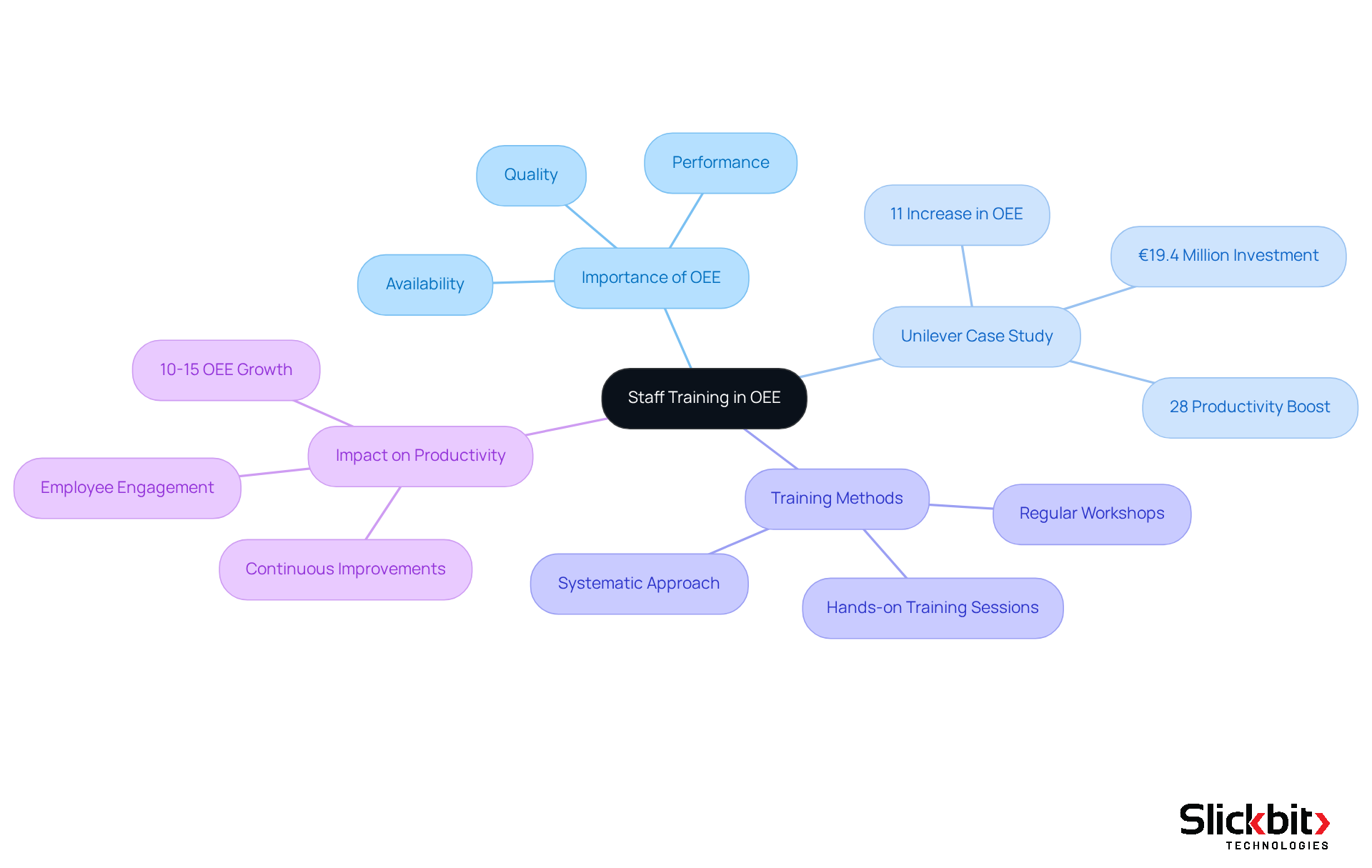

Staff Training: Empower Teams with OEE Knowledge

Empowering teams with a comprehensive understanding of OEE for manufacturing metrics is crucial for fostering a more engaged workforce. Training programs must highlight the importance of availability, performance, and quality, allowing employees to recognize their roles in enhancing OEE for manufacturing.

For instance, Unilever's initiative across its factories led to a remarkable 28% boost in productivity and an 11% increase in OEE, illustrating the substantial benefits derived from investing in employee training. The €19.4 million investment at Unilever’s Poznan factory exemplifies a strong commitment to training and its potential impact on OEE for manufacturing.

Regular workshops and hands-on training sessions can equip staff with the skills needed to effectively leverage data, driving continuous improvements. Furthermore, a systematic approach to training can result in a 10-15% growth in OEE for manufacturing within the initial years of implementation, as evidenced by various manufacturing sites, including a notable 16% increase in OEE for manufacturing scores at Kilbourn.

By nurturing an environment where employees are encouraged to engage with OEE for manufacturing metrics, companies can unlock significant productivity gains and enhance overall operational efficiency. Richard's insight that "it is only when groups and technology are working in harmony that we can achieve the optimized productivity we are aiming for" further underscores the essential role of training in this context.

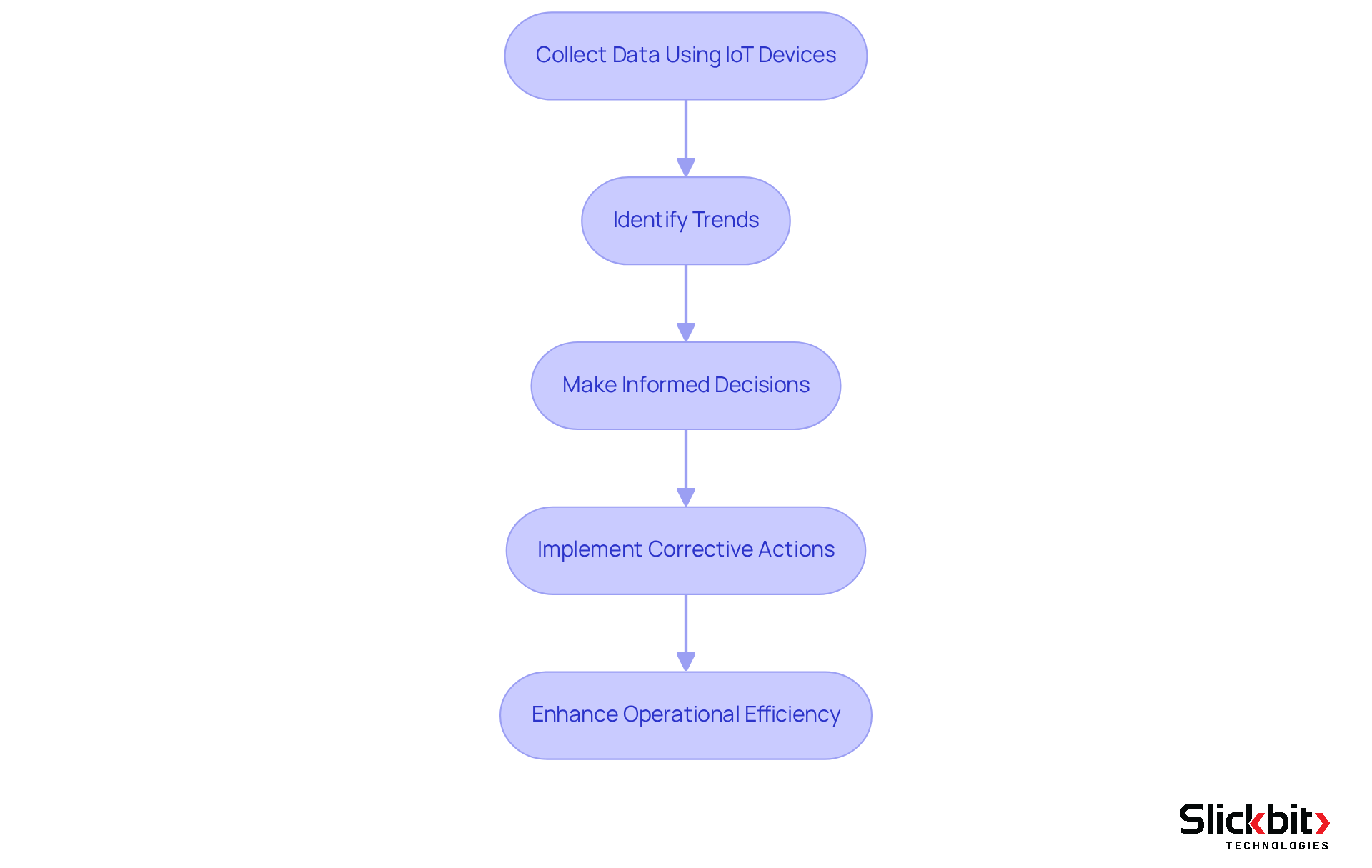

Real-Time Data Analytics: Monitor and Improve Performance

Real-time data analytics empowers manufacturers, particularly in the Life Sciences sector, to continuously monitor OEE for manufacturing metrics. By integrating IoT devices such as Vorne XL displays and other smart sensors, companies can collect critical data on machine performance. This enables them to identify trends and make swift, informed decisions. Consequently, this proactive strategy facilitates immediate corrective actions, significantly reducing downtime and enhancing production efficiency.

For instance, entities utilizing IoT for OEE for manufacturing monitoring have reported a 15% rise in operational efficiency, according to McKinsey & Company, underscoring the transformative effect of these technologies. Furthermore, real-time insights allow teams to address issues as they arise, ensuring that production processes remain optimized and aligned with strategic goals.

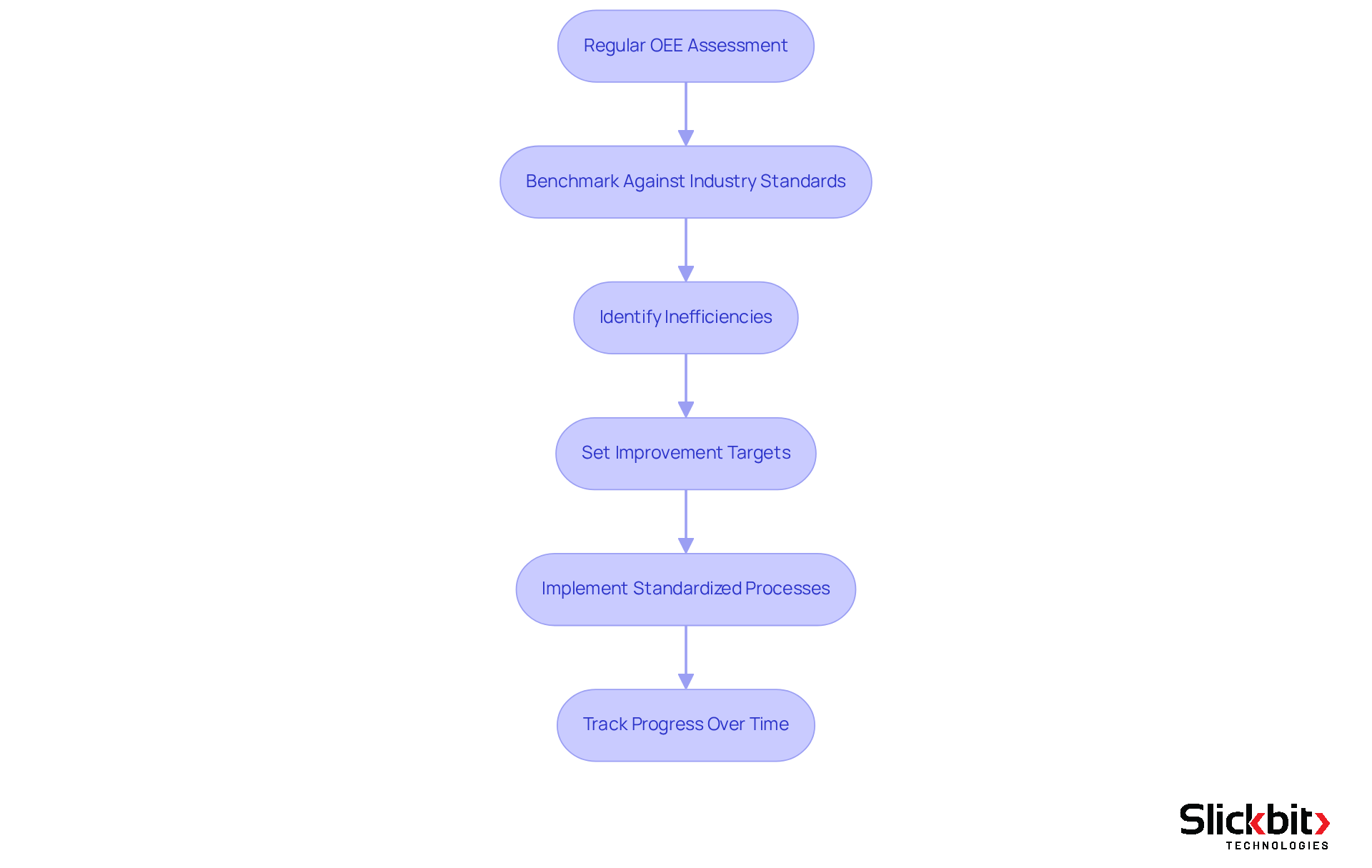

Regular OEE Assessments: Identify and Track Improvement Areas

Regular OEE for manufacturing assessments are essential for manufacturers seeking to enhance operational effectiveness. By systematically evaluating OEE for manufacturing data, organizations can benchmark their performance against industry standards, which typically see world-class scores around 85%. Notably, many manufacturing lines operate at only 60% productivity, indicating substantial opportunities for improvement. This benchmarking process is instrumental in identifying specific inefficiencies, enabling teams to establish realistic improvement targets. For instance, a 40% OEE is common for companies just beginning to monitor their performance, underscoring significant potential for enhancement.

Moreover, these assessments enable the tracking of progress over time, ensuring that manufacturers can continuously refine their processes to enhance OEE for manufacturing. Real-world examples illustrate that entities implementing standardized processes and training employees to address minor issues in real time can markedly reduce operational losses. A case study on minimizing loss through standardized processes reveals that by empowering workers to resolve simple issues as they arise, organizations can maintain smoother production flows. By fostering a culture of continuous improvement through regular evaluations of OEE for manufacturing, manufacturers can not only increase productivity but also sustain a competitive advantage in the industry.

Lean Manufacturing: Streamline Processes to Reduce Waste

Implementing lean manufacturing practices necessitates a comprehensive analysis of workflows to eradicate non-value-added activities. By concentrating on continuous improvement and waste reduction, manufacturers can significantly elevate their OEE for manufacturing scores. Typically, a benchmark of 60% is observed for discrete manufacturers, with 85% considered world-class. Techniques such as value stream mapping serve to visually represent production processes, enabling teams to pinpoint inefficiencies and optimize operations. Furthermore, the 5S methodology—Sort, Set in order, Shine, Standardize, Sustain—ensures that the workplace remains organized and efficient, facilitating optimal resource utilization and enhanced productivity.

Moreover, fostering a culture of continuous improvement is essential, achievable through active employee engagement in lean initiatives. Predictive maintenance also plays a pivotal role in mitigating downtime, thereby enhancing OEE for manufacturing. To implement these strategies effectively, manufacturers should routinely evaluate their processes and encourage team members to propose enhancements, cultivating an environment where continuous progress is the norm.

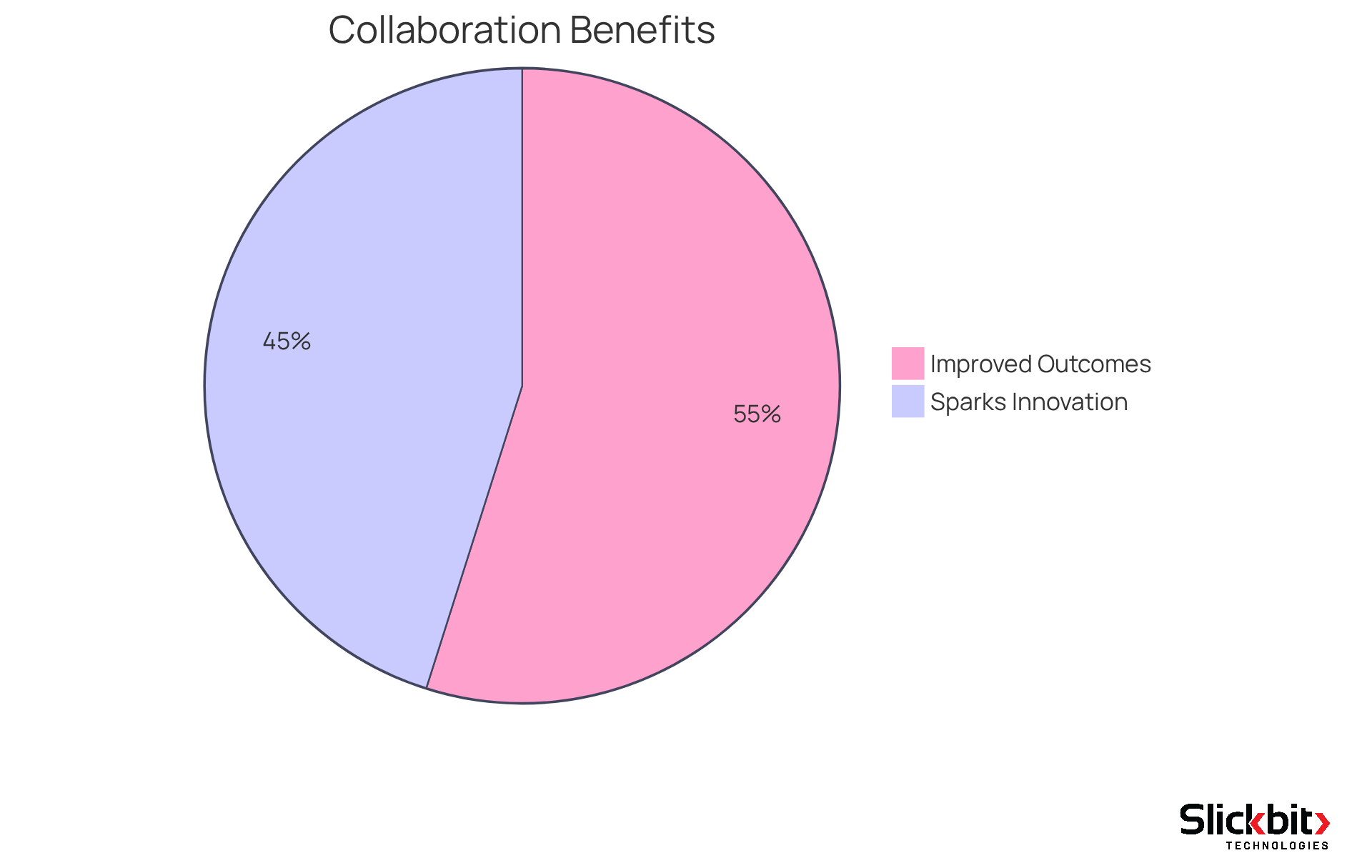

Cross-Functional Collaboration: Foster Teamwork for OEE Success

Cross-functional collaboration is essential for enhancing OEE for manufacturing. By breaking down silos and fostering open communication, organizations can leverage the diverse expertise across various departments. Regular meetings and collaborative projects not only align goals but also promote the sharing of insights, resulting in significant improvements in equipment effectiveness and overall productivity.

Research shows that utilizing cross-disciplinary groups can bolster initiatives related to OEE for manufacturing, enabling better identification and resolution of production performance losses attributed to both chronic and sporadic disturbances. Furthermore, organizations prioritizing teamwork experience a notable increase in performance metrics; studies reveal that:

- 73% of employees engaged in collaborative work report improved outcomes

- 60% assert that collaboration ignites innovation

This collaborative approach not only nurtures innovation but also enhances responsiveness to market changes, ultimately propelling manufacturing success. As Christopher J. Bamber aptly notes, "the most successful method of employing OEE for manufacturing is to use cross-functional teams aimed at improving the competitiveness of business.

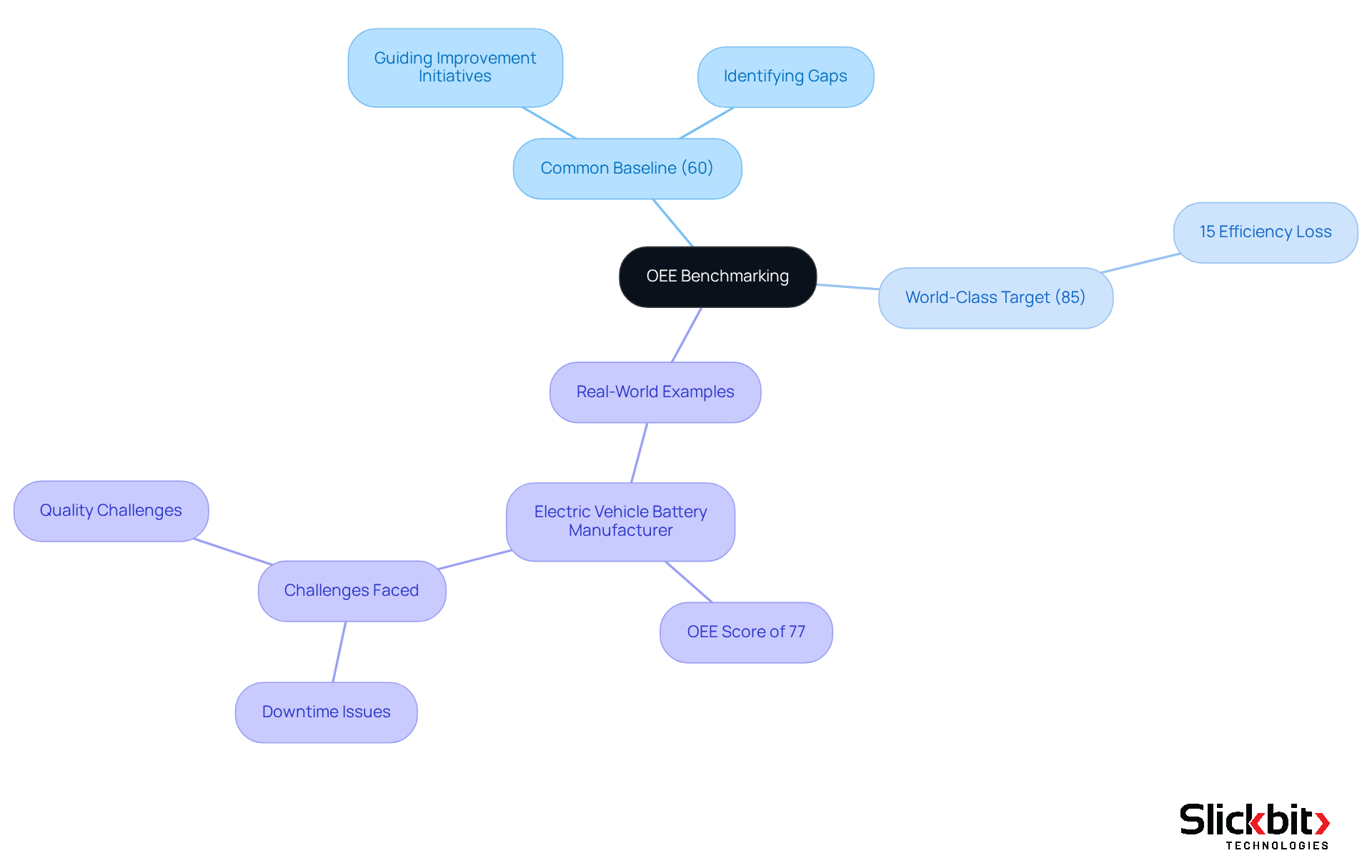

Benchmarking: Set Realistic OEE Targets for Improvement

Establishing realistic OEE for manufacturing benchmarks is crucial for guiding improvement initiatives in the manufacturing sector. Many manufacturing lines operate at only 60% productivity, making this score a common baseline for organizations aiming to enhance their performance.

By measuring performance against industry standards, manufacturers can identify gaps and set attainable targets. For example, an OEE score of 60% is frequently recommended as a practical goal before striving for higher objectives, while an 85% score is deemed world-class, illustrating that even leading companies face a 15% loss in potential production due to inefficiencies.

This benchmarking process not only inspires teams but also offers a structured framework for assessing progress and success in boosting overall equipment effectiveness. Real-world examples, such as an Electric Vehicle battery manufacturer achieving a score of 77% after addressing downtime and quality challenges, underscore the tangible benefits of establishing realistic OEE goals.

This score reflects the obstacles encountered in production, highlighting the need for continuous improvement. By tracking OEE for manufacturing performance against industry benchmarks, companies can identify enhancement opportunities and promote operational excellence. OEE for manufacturing serves as both a benchmark for evaluating production asset performance against industry standards and a baseline for monitoring progress in reducing waste over time.

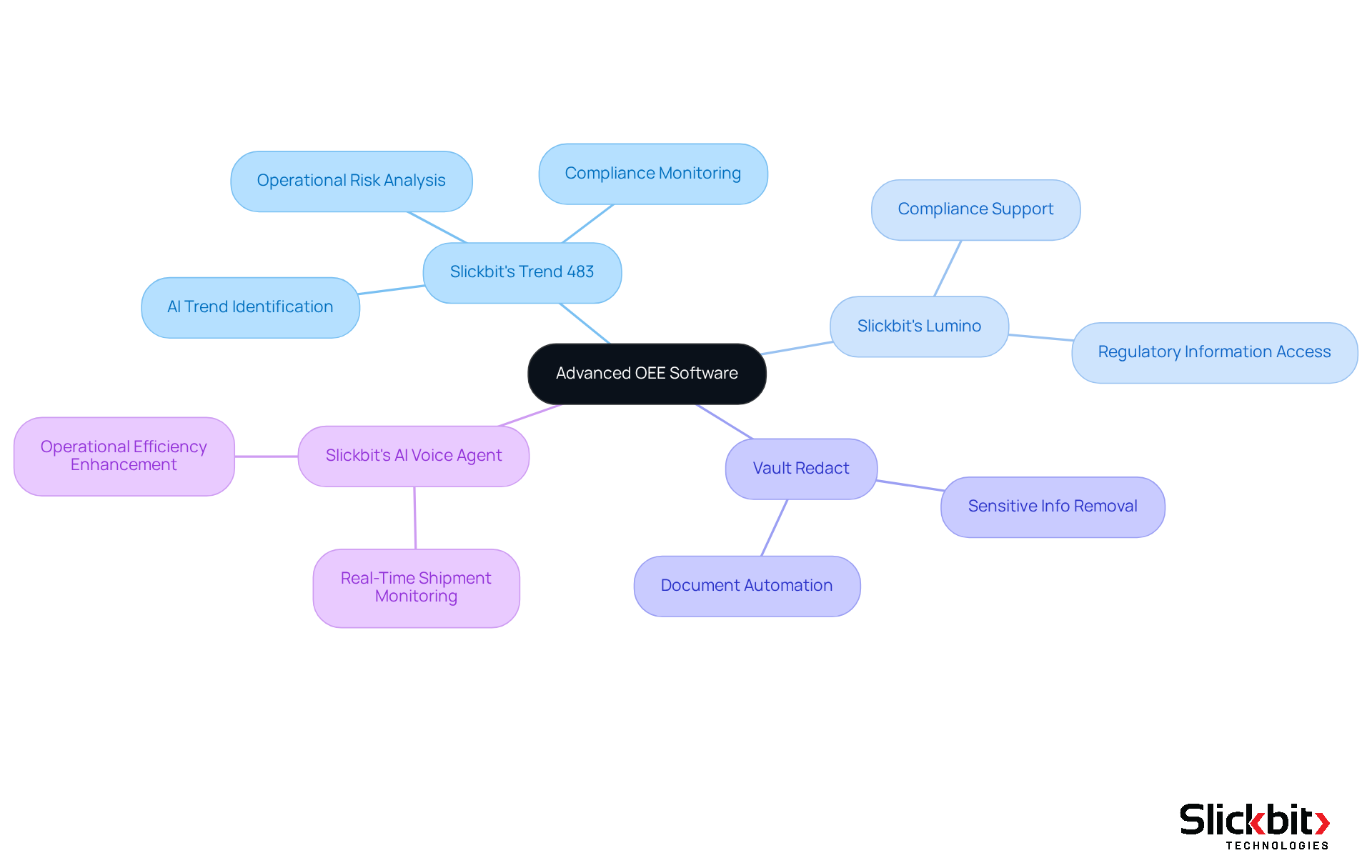

Advanced OEE Software: Automate Calculations and Gain Insights

Investing in advanced software for OEE for manufacturing is crucial for streamlining the tracking and analysis of performance metrics. Tools such as Slickbit's Trend 483 leverage AI to identify trends in compliance and operational risks, thereby equipping manufacturers with profound insights into their performance. These solutions not only automate calculations but also offer real-time dashboards tailored to specific metrics, generating actionable insights that empower organizations to make data-driven decisions with agility.

Furthermore, Slickbit's Lumino aids pharmaceutical teams in accessing precise regulatory information, while Vault Redact automates the identification and removal of sensitive information from documents. In addition, Slickbit's AI Voice Agent for Shipment Alerts enhances operational efficiency by monitoring shipments in real time. By harnessing these technologies, organizations can significantly improve their ability to track OEE for manufacturing and implement effective enhancements, ultimately driving operational excellence.

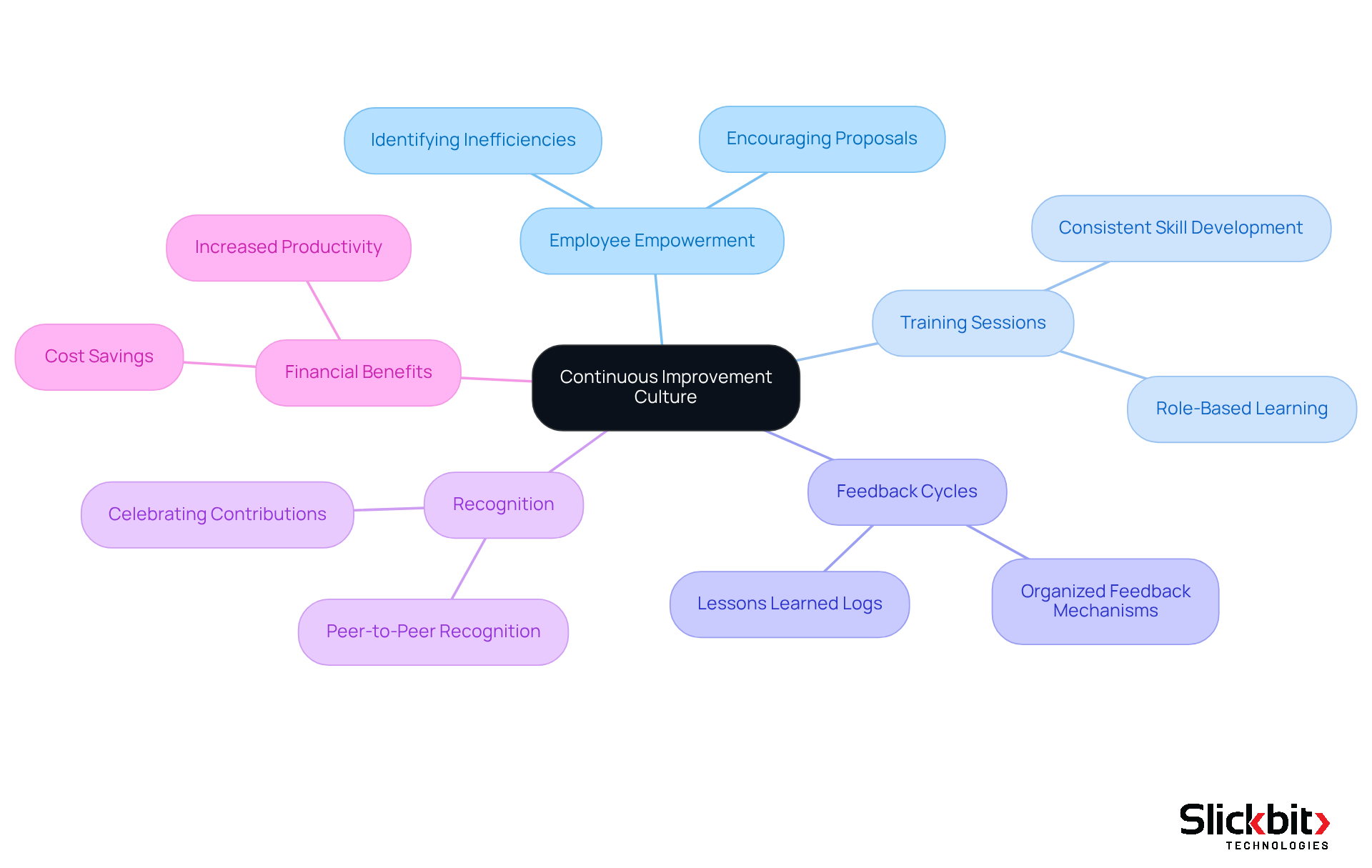

Continuous Improvement Culture: Foster Ongoing OEE Enhancements

Nurturing a culture of ongoing development is essential for sustaining and boosting OEE for manufacturing over time. This culture empowers employees at all levels to identify inefficiencies and propose actionable solutions. Consistent training sessions and organized feedback cycles foster an atmosphere where members feel appreciated and driven to participate in continuous advancement efforts. Acknowledging and celebrating individual and group contributions not only enhances morale but also emphasizes the significance of OEE for manufacturing as a strategic priority within the organization.

Organizations that have effectively adopted employee-driven enhancements report considerable increases in productivity and efficiency, demonstrating that when employees are involved, the potential for OEE for manufacturing enhancements is maximized. John Buchanan observed that the ideal team enhances each day, irrespective of who joins, emphasizing the core of ongoing advancement. Furthermore, organizations that have embraced peer-to-peer recognition systems, like those established by Willemijn Schneyder, have seen enhanced employee engagement.

Significantly, top-tier firms have monitored and conserved over $1.4 billion with KPI Fire, highlighting the financial advantages of a strong continuous enhancement culture. By embedding continuous improvement into the organizational fabric, manufacturers can ensure that OEE for manufacturing remains a central focus for operational excellence.

Conclusion

Boosting Overall Equipment Effectiveness (OEE) in manufacturing is not merely a goal; it is an essential requirement for achieving operational excellence and sustaining a competitive advantage. By implementing strategies such as AI integration, predictive maintenance, staff training, and real-time data analytics, manufacturers can significantly enhance their productivity and efficiency. Collectively, these approaches empower organizations to identify inefficiencies, reduce downtime, and optimize resource utilization, ultimately leading to improved OEE scores.

The article delineates several key strategies, including:

- The critical importance of fostering a culture of continuous improvement

- Leveraging advanced software solutions

- Embracing lean manufacturing principles

Regular assessments and benchmarking against industry standards establish a framework for tracking progress and setting realistic targets. Furthermore, cross-functional collaboration among teams enhances communication and innovation, driving additional improvements in equipment effectiveness.

In conclusion, the journey to optimize OEE necessitates a multifaceted approach that integrates technology, training, and teamwork. Manufacturers are urged to adopt these strategies proactively, cultivating an environment where continuous improvement becomes ingrained in their operations. By doing so, organizations can not only enhance their OEE but also strategically position themselves for long-term success in a rapidly evolving manufacturing landscape.

Frequently Asked Questions

What is Slickbit and how does it enhance OEE for manufacturing?

Slickbit is a provider of AI solutions that optimize Overall Equipment Effectiveness (OEE) in manufacturing by automating data collection, enabling predictive maintenance, and offering real-time analytics. This helps companies identify inefficiencies, minimize downtime, and improve equipment utilization.

How does predictive maintenance contribute to equipment reliability and uptime?

Predictive maintenance uses AI algorithms to analyze historical and real-time data to predict equipment failures. This proactive approach can reduce downtime by 35% to 45%, decrease equipment breakdowns by 70%, and lower maintenance costs by up to 25%, thus enhancing overall operational efficiency.

What are some real-world applications of Slickbit's AI solutions?

One example is the Festo AX Motions Insights Pneumatic app, which monitors pneumatic systems for anomalies, preventing costly machine failures and boosting productivity. Such applications demonstrate how AI can facilitate continuous monitoring and proactive interventions in manufacturing.

What impact does staff training have on OEE for manufacturing?

Staff training is crucial for improving OEE metrics, as it helps employees understand their roles in enhancing availability, performance, and quality. For instance, Unilever's training initiatives led to a 28% increase in productivity and an 11% rise in OEE.

How can organizations implement effective training programs for OEE?

Organizations can implement regular workshops and hands-on training sessions to equip staff with the necessary skills to leverage data effectively. A systematic approach to training can lead to a 10-15% increase in OEE within the first few years of implementation.

What is the significance of AI Integration Services offered by Slickbit?

Slickbit's AI Integration Services facilitate the seamless incorporation of AI into existing systems, enhancing operational efficiency and allowing manufacturers to leverage AI technologies effectively in their workflows.

How does the implementation of predictive maintenance affect maintenance schedules?

Predictive maintenance allows for the optimization of maintenance schedules, enabling repairs to be conducted during off-peak hours, which minimizes disruptions and enhances production continuity.